Barrier Screw

● Blown film ● Cast film

● Pipe extrusion ● Sheet extrusion

● High speed single screw extrusion

● LDPE, LLDPE, HDPE, PP

You Need Better Barrier Screw at Good Price

- Product Detail

HUACHEN Screw has been a leading Barrier Screw manufacturer in Zhoushan Jintang since 2005. With many years of experience in designing and processing plastic machinery accessories, HUACHEN Screw can provide its customers with a wide range of services, including drawing rebuilding, design, modification, and customization. Our company has also successfully exported and supplied screw barrels to customers worldwide.

>>Learn More About Our Company

What Is A Barrier Screw?

In addition to the classic screw design with three stages, there are also screw designs with mixing structures for better mixing and plasticising. Most of these mixing structures are at the head of the compression and metering section. The barrier BM screw is one of the most common types.

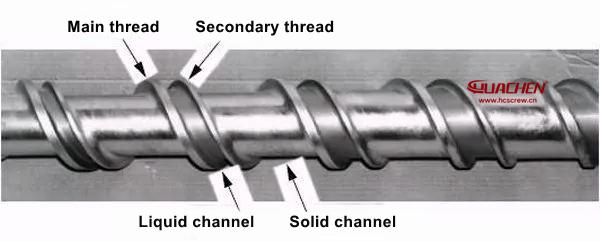

A barrier screw (or barrier flight screw) is a new type of single screw based on the common three-stage screw, with a similar basic mechanism. Unlike other screws, this one has two threads. It is either a front thread and a rear thread with unequal lead lengths or the main thread and a secondary thread with the same lead length. When the solid phase melts and crosses the gap, it forms a molten film that crosses the liquid phase screw groove. This leaves the uncontained solid phase in the solid phase groove. The name barrier screw comes from that.

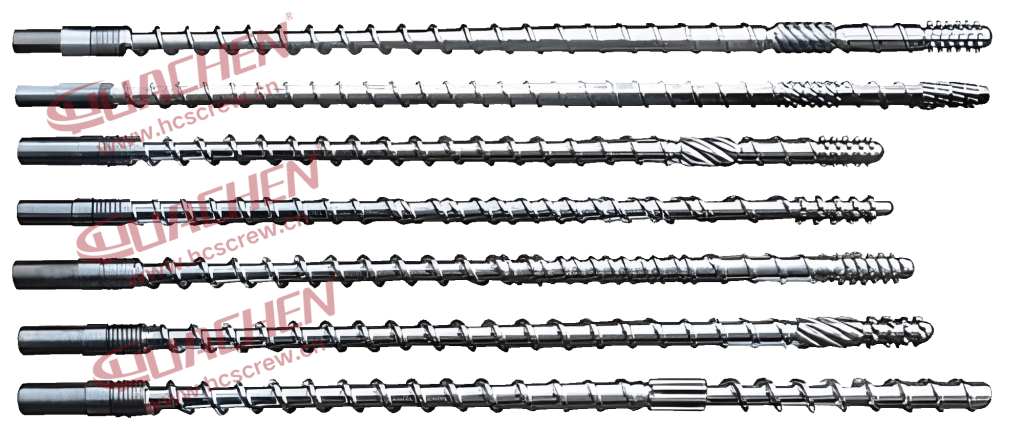

These are some of the barrier screw design we use: Maillerfer screw(BM screw), Barr screw, Dray/Lawrence screw. Based on the plastic products you need to produce, we can recommend the best barrier screw design for you.

What Is The Advantage Of Barrier Screws?

1. Only melted plastic can get into the liquid phase screw tank. When passing through the gap, small particles that haven’t been fully plasticized can also be fully plasticized. As soon as the liquid phase separates, the solid phase comes into direct contact with the high temperature barrel inner wall, accelerating the melting.

2. A screw’s metering section isn’t always the same length as the theoretical length due to different plastic pressures, mouth mould pressures, and operating conditions. With the barrier screw design, the liquid phase screw groove is almost molten, so the length of the metering section is stable.

3. With a barrier screw, the air between the solids and the water vapour can escape more easily under pressure.

4. The screw doesn’t break the solid phase because it doesn’t have uneven radial pressure at all points. Since broken solid phase fragments are embedded in the gap between the screw and the barrel, the solid phase doesn’t distribute evenly. It’s the same as a normal screw.

5. Barrier screws have a deeper groove, so they have a smaller shear speed gradient, so melt won’t break down at high speeds. Because of this, you can drive the barrier screw at higher speeds and still maintain quality.

What Is The Application Of Barrier Screws?

Barrier screws have many advantages over conventional screws, including a high melting rate and high productivity. It has a low melting point and is very stable. It is suitable for the efficient production of PE blown film, casting film, PE/PP sheet, and pipe. The combination of this extruder configuration with the optional grooved feeding barrel makes for a highly efficient and high speed plastic grooved feeding barrel extrusion.

Despite this, the high pressures generated by the barrier screw can lead to wear and tear, which requires a premium barrier screw manufacturer with rich experience.

HUACHEN Barrier Screw Specifications

1. Single screw diameter available: 25 mm to 300 mm

2. Single screw L/D ratio available: 15 to 40

3. Max. length: ≤10000 mm

4. Based materials: Premium 38CrMoAlA (UNS K24065, SACM645, 41CrAlMo7-10)

5. Plasma nitriding surface hardness: HV 1000-1100

6. Plasma nitriding depth: ≥ 0.7 mm

7. Nitriding time: more than 120 hours

8. Nitriding fragility: less than Grade I.

9. Hardness of the nitride layer after grinding off 0.20 mm: ≥ 760 (38CrMoALA).

10. Surface Roughness: Ra 0.4 μm

11. Screw Linearity: ≤ 0.015mm

12. Alloy depth: 2-4 mm

13. Alloy surface hardness: ≥ HRC 61

14. Chromium coating thickness: 0.03-0.05 mm

>>Learn more about our barrier screw parameters

Production time:

within 15–28 days, depending on the complexity of the part.

Call or mail us for more details and a discussion about barrier screws and technology!