Ceramic Coating Alloy Screw Barrel

● Min. Order (MOQ): 2 screws + 1 barrel / Set

● PVC wall panels, siding panel extrusion

● Wood plastic composite sheet or board extrusion

● Stone plastic composite sheet or board extrusion

● Rigid vinyl plank flooring making extrusion

You Need Better Ceramic Coating Alloy Screw Barrel at Good Price!

- Product Detail

The ceramic alloy screw barrel manufacturer HUACHEN Screw has been operating in Zhoushan Jintang since 2005. As a manufacturer of plastic machinery extrusion parts, HUACHEN Screw offers its customers a wide range of services. This includes designing, rebuilding, modifying, and upgrading screw barrels. We have also successfully exported and supplied screw barrels to customers worldwide.

>>Learn More About Our Company

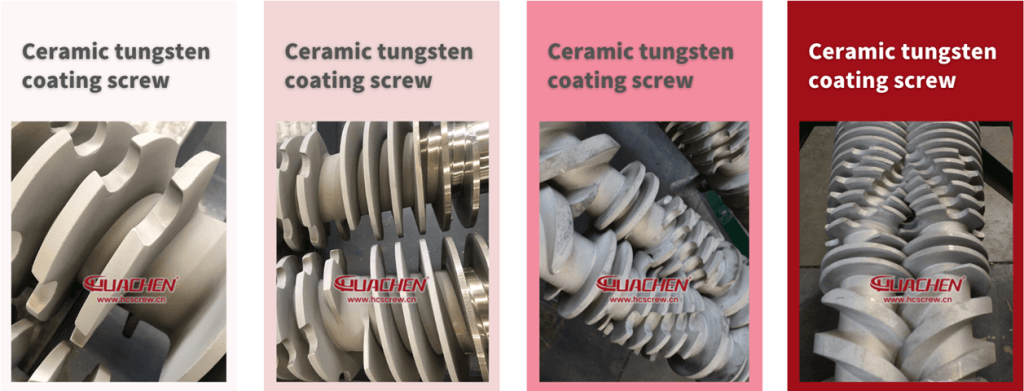

Ceramic coating alloy screw barrel

The screw and reinforcement process was developed for users of stone plastic composites and PVC rigid vinyl plank extruders with fillers above 600%. As a wear-resistant solution for twin screws, chrome plating should be familiar to users. When processing rigid vinyl plank materials such as stone-plastic PVC, a chrome-plated screw is still not strong enough to resist wear. In order to replace chrome on chrome-plated screws, we are upgrading them with a ceramic tungsten alloy that has enhanced strength and performance. In place of chrome plating, a full coating is applied to the screw’s key wear-flight areas. A complete ceramic tungsten coating covers the underside of the screw flights, including the sides and surface. The ceramic tungsten alloy screw has a more rigid metal surface and is more wear-resistant, according to user feedback.

The ceramic tungsten alloy is 0.05-0.1 mm thick and tightly coated on the screw surface to ensure that it does not flake off during use and affect the quality.

A set of ceramic tungsten alloy screws made from nitrided steel with a bimetallic alloy process to strengthen wear-prone areas. And a ceramic tungsten coating is applied to the screw’s key strengthening areas.

Advantages of HUACHEN ceramic coating alloy screw

1. Fine material reduces microcracking and porosity in chrome plating

2. Improves corrosion resistance

3. improve resistance to abrasion

4. increase the hardness of the plated layer

5. increase the bond strength of the plating

6. reduced polymer adhesion, avoiding screw stickiness and scorching

7. reduced screw cleaning time

Application of ceramic coating alloy screw

1. WPC conical twin screw for planks, door sheets, board extrusion

2. SPC conical twin screw for rigid vinyl plank sheet board extrusion

Materials

1. Based materials: Premium 38CrMoAlA

2. Plasma nitriding surface hardness: HV 1000-1100

3. Plasma nitriding depth: ≥ 0.7 mm

9. Nitriding fragility: less than Grade I.

11. Surface Roughness: Ra 0.4 μm

12. Screw Linearity: ≤ 0.015mm

13. Ceramic tungsten coating thickness (optional): 0.05-0.10 mm

14. Ceramic tungsten coating layer hardness (optional): ≥ HV 950

>>Learn more about our ceramic alloy screw barrel parameters

Production time

Complete set of screw barrel within 33-40 days depending on the complexity of the part.

We have a wide selection at good prices to help you get creative. The ceramic coating alloy screw barrel for Sale is guaranteed to be of high quality. We are the China Origin Factory of ceramic coating alloy screw barrel. If you have any questions, please feel free to contact us.