PET Melting Temperature and Processing Guide

Date:2022-11-14 Author:hcscrew

PET is made from polyethylene terephthalate, the most common type of thermoplastic polyester (shortened to PEIT or polyethylene terephthalate), commonly known as polyester resin. It’s a condensation of terephthalic acid, ethylene glycol, and PBT, collectively called thermoplastic polyester.

PET melting temperature and features

PET is a very light weight polymer with crystallinity ranging from amorphous to fairly highly crystalline and the ability to be semi-rigid to rigid depending on thickness. It’s naturally colorless and transparent, but thicker sections tend to be translucent and off-white.

PET density 1.3-1.4 g/cm3

Glass transition temperature 73-78 ℃

Max/Min.continuous Service temperature 80-140 ℃/-40 ℃

Melting Temperature 250 ℃

Processing methods

Absorbs moisture, so pre-drying before processing is highly recommended for 2-4 hours at 120 ℃.

PET can be Injection moulded, Thermoformed, Extruded, and Blow moulded.

For injection moulding, a melt temperature of 280-310°C is recommended. For crystalline PET, mould temperatures of 140-160 °C are recommended, and transparent applications should be between 10 and 50 °C.

Extrusions with melt temperatures of 270-290 °C are typically used to produce films and sheets (can also be thermoformed later).).

Blow moulding is generally used to produce transparent bottles with a moulding temperature between 10 and 50 ℃.

Strengths

PET has excellent wear resistance and electrical properties, with a low coefficient of friction, high flexural modulus, and superior dimensional stability. It also has broad operating temperatures, low gas permeability, such as carbon dioxide, FDA compliance, transparency to microwave radiation, and more strength & stiffness than PBT. Among general-purpose engineering thermoplastics, PET has the highest HDT and long-term use temperature. There’s no center line porosity in PET, so there’s no chance of fluid absorption.

Limitations

Due to its slow crystallization rate, PET is not recommended for outdoor use or in hot water, it burns poorly, and it doesn’t mould as well as PBT.

Applications

It could manufacture bottles of mineral water and soft drinks, cosmetic jars, microwaveable containers, transparent films, electrical plugs, housings for appliances, MPET for flexible food packaging and thermal insulation, magnetic tape, backing for pressure-sensitive adhesive tapes, packaging trays and blisters, thermoformed food containers, signs and display boards, disposable coffee cups, and glasses.

Summary

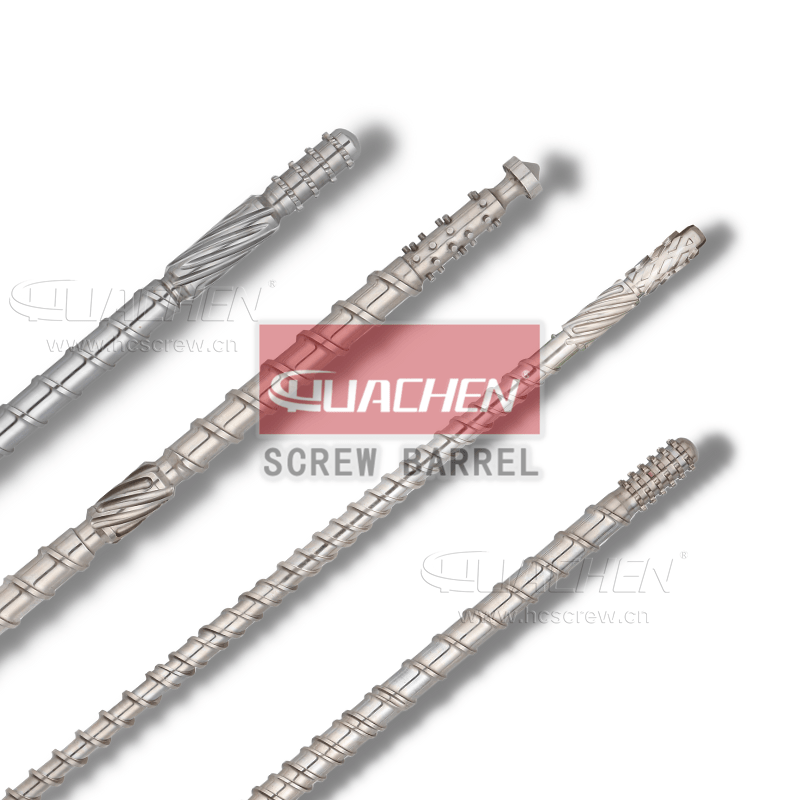

Understanding the melting point of PET plastic is critical for designing and optimizing the screw barrel structure for PET extruders. As well as helping customers choose a high-quality PET extrusion screw barrel. For more information about the melting points of PET plastics when processed through an excellent extruder screw, please feel free to contact us.

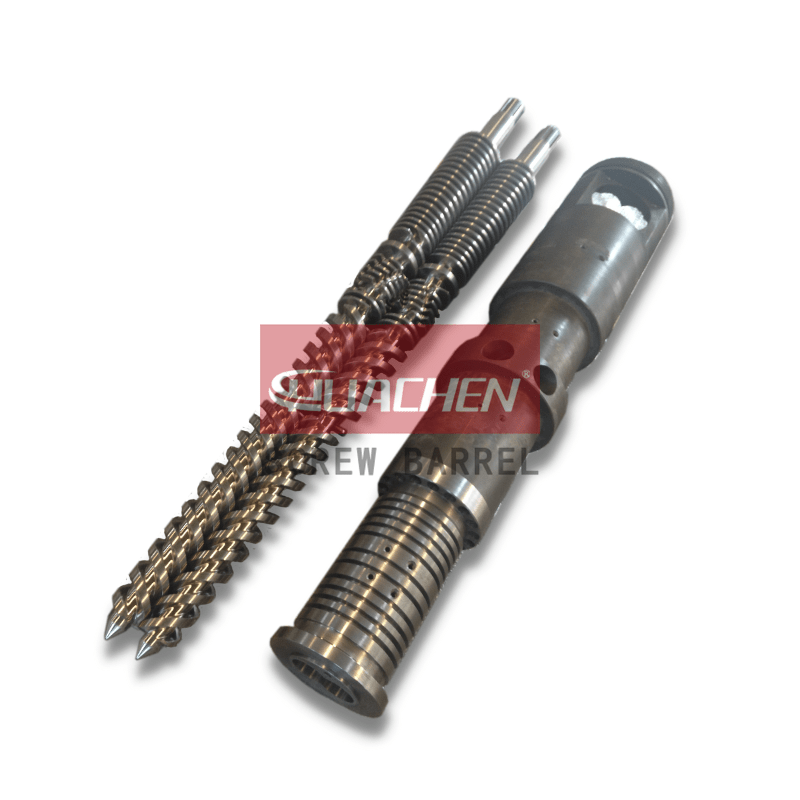

About the screw barrel manufacturer: HUACHEN

HUACHEN Screw has been a leading PET extrusion screw barrel manufacturer in Zhoushan Jintang since 1993. As one of the leading companies in designing and processing PET single screw extrusion spare parts screw barrel, HUACHEN Screw can provide its customers with a wide range of services, including drawing rebuilding, design, modification, and customized screw barrels. Our company has also successfully exported and supplied screw barrels to customers worldwide.

>>Learn more about our company

You May Also Like

| Blown Film Extruder Screw Barrel ↗ Get details & quote for blown film extruder screw barrel. Bimetallic alloy anti-wear screw barrels for better plastic film making at HUACHEN. |

| Plastic Recycle Pellets Granulation Machine Screw Barrel ↗ Details and price of heavy duty plastic recycle pellets granulation machine screw barrel, find upgraded pelletizing screw barrel at HUACHEN |

TAGS

HUACHEN Screw barrel recent post

- Boosting Efficiency and Quality: HUACHEN Screw Barrel’s Unmissable Showcase at HanoiPlas 2023

- Pipe Extrusion Operation: Best Practices for High-Quality Products

- Expert Maintenance Tips for Long-Lasting Bimetallic Alloy Screw Barrels

- Reviving Your Extruder: The Importance of Choosing the Right Screw Barrel Replacement

- Solutions to Common Production Problems for Rigid PVC Profiles and Pipes

- Customized Twin Screw Barrel with Internal Bore Grooves Sprayed with Bimetallic Alloy

- Troubleshooting Vent Flow Material Problems in PVC Profile Formation with Conical Twin Screw Extruders

- A Comprehensive Guide to Popular PVC Profiles and Their Production Methods

conical twin screw barrel extruder screw barrel extrusion screw barrel Foam sheet processing high speed screw barrel HUACHEN SCREW news injection screw barrel parallel twin screw barrel pa screw barrel pe making formula pe screw barrel plastic fiber processing plastic fibre screw barrel Plastic film making screw barrel plastic pipe processing Plastic profile processing Plastic raw material knowledge pp screw barrel PVC making formula pvc screw barrel related parts for screw barrel screw barrel engineering work screw barrel knowledge single screw barrel twin screw barrel

;