Spunbond Nonwoven Fabric Screw Barrel

● Min. Order (MOQ): 1 screw + 1 barrel / Set

● PP, PE, PET

● Spunbond nonwoven. Medical and hygiene convenience nonwovens, nonwovens for packaging materials and lining wrapping, agricultural mulching materials

You Need Better Spunbond Nonwoven Fabric Extruder Screw Barrel at Good Price!

- Product Detail

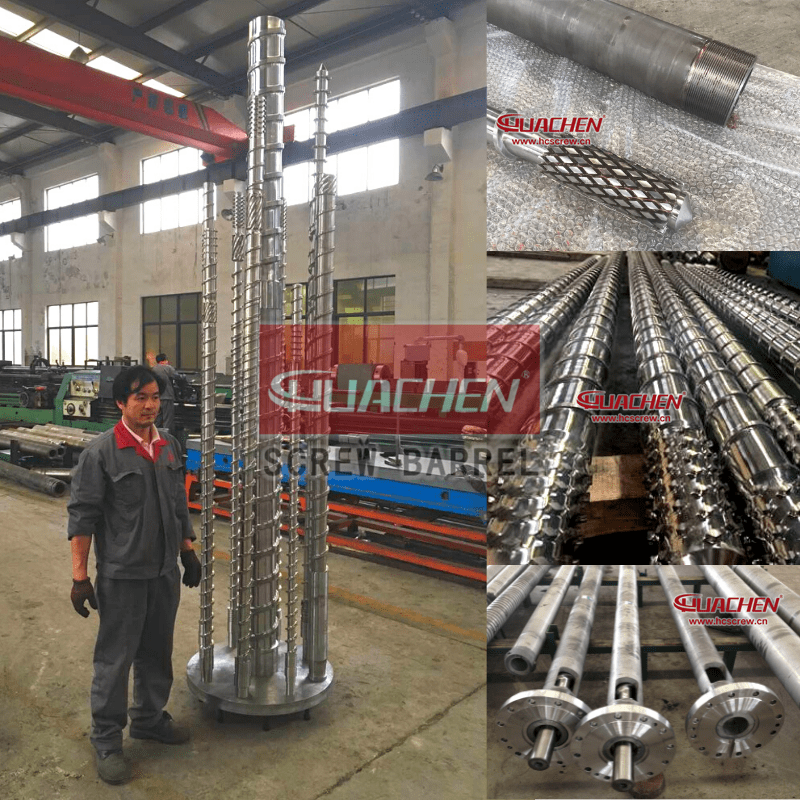

HUACHEN Screw has been a top producer of spunbond nonwoven extruder screw barrel in Zhoushan Jintang since 1993. With many years of experience designing and processing plastic machinery accessories, HUACHEN Screw can provide its customers with a wide range of services, including drawing rebuilding, design, modification, and customization. Our company has also successfully exported and supplied screw barrels to customers worldwide.

>>Learn more about our company

Spunbond nonwoven fabric extruder screw barrel

The spunbond nonwovens are produced by extruding polymers (PP, PE, PET) and stretching them to form continuous filaments, which are then laid out into a web, which are then reinforced mechanically, thermally, or chemically to form nonwoven fabrics.

We have a wide range of large barrel screw processing equipment for producing high quality spunbond nonwoven extrusion screw barrels (D90, D105, D120, D135). Aside from common screw designs, we also offer optimized special screws. By increasing the melt and compression time of the screw, the nonwoven material is transported with complete compression, resulting in a more homogeneous, dense product. This ensures the quality of spunbonded nonwovens. Moreover, the feed material is stable and the output of the extrusion section is balanced, which improves plasticisation and extrusion efficiency.

The spunbond nonwoven screw barrel is made of high quality 38CrMoAlA, which is tempered and nitrided to ensure its hardness, various indicators, and long-term service life are excellent.

| Spunbond nonwoven fabric SB model | Screw L/D ratio | Screw rpm(r/min) | Drive motor power | Max. output(kg/h) |

|---|---|---|---|---|

| φ120 | 30 | 75 | 75 | 200 |

| φ130 | 30/32 | 75 | 90 | 220 |

| φ135 | 30/32 | 75 | 90 | 260 |

| φ150 | 30/32 | 70 | 110 | 350 |

| φ160 | 30/32 | 70 | 110 | 400 |

| φ170 | 30/32 | 60 | 132 | 450 |

| φ180 | 30/32 | 60 | 160 | 500 |

>> Learn more about our meltblown nonwoven fabric screw barrel

Spunbond nonwoven fabric waste recycling screw barrel

In the production of spunbond nonwoven fabrics, the nonwoven is cut into rolls to ensure the quality of the finished product and to make it neat and attractive. Moreover, after the product has been slit, there is also waste material because the customer requires different widths and sizes. On average, nonwoven fabric trimmings make up 8% to 25% of the total product volume. Timely recycling of waste is essential. In most spunbond nonwoven plants, an extruder with a recycling screw is used.

| Spunbond nonwoven fabric waste recycling SB model | Screw L/D ratio | Screw rpm(r/min) | Drive motor power |

|---|---|---|---|

| φ105 | 15 | 110 | 18.5 |

| φ120 | 15 | 100 | 22 |

Parameters

1. Single screw diameter available: 45 mm to 180 mm

2. Single screw L/D ratio available: 15 to 33

3. Screw max. length: ≤10000 mm

4. Barrel max. out diameter: ≤350 mm

5. Based materials: Premium 38CrMoAlA

6. Plasma nitriding surface hardness: HV 1000-1100

7. Plasma nitriding depth: ≥ 0.7 mm

9. Nitriding fragility: less than Grade I.

10. Surface Roughness: Ra 0.4 μm

11. Screw Linearity: ≤ 0.015mm

12. Alloy depth: 2-4 mm

13. Alloy surface hardness: ≥ HRC 61

>>Learn more about our spunbond nonwoven fabric extruder screw barrel parameters

Production time

Complete set of spunbound nonwoven fabric screw barrel within 20-30 days depending on the complexity of the part.

We have a wide selection at good prices to help you get creative. The spunbond nonwoven screw barrel for Sale is guaranteed to be of high quality. We are the China Origin Factory of spunbond nonwoven fabric screw barrels. If you have any questions, please feel free to contact us.