What Is The Twin Screw Extruder Structure And Parts?

Date:2022-5-21 Author:hcscrew

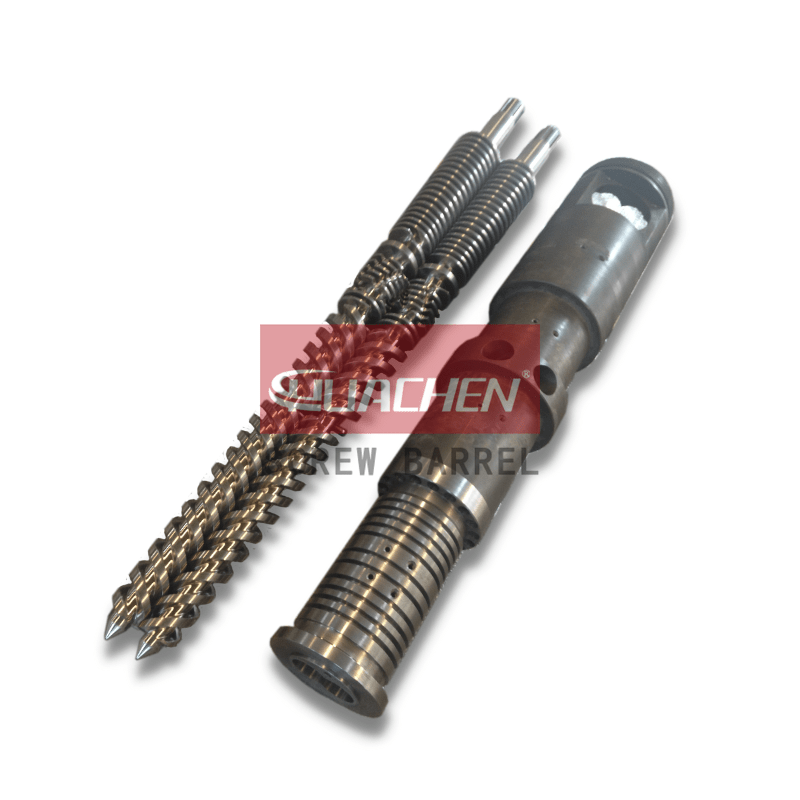

1. What is twin screw extruder parts

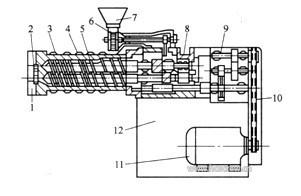

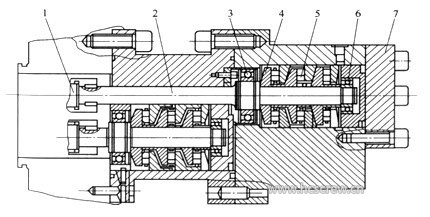

The parts of a twin screw extruder are quite similar to single screw extruder parts. The twin screw extruder has two screws in the barrel, the feeding section employs a screw to drive the material into the barrel, and the specifications and arrangement of the screw bearings are more sophisticated. Figure 1 depicts the position of the components of the twin-screw extruder.

1 —connection flange; 2 —manifold; 3 —barrel; 4 —barrel heater; 5 —twin screw

6 —Auger charging device; 7 —Hopper; 8 —Screw bearing; 9 —Extruder parts gearbox reducer.

10 —conveyor belt; 11—motor; 12 —Machine frame

2. What is twin screw extruder screw structure?

There are several types of screw structures in the twin screw extruder. In the classification of twin screw extruder, there are different screws and screw combinations engaged with or without the type of screw; screw threaded portion of the composition; and the form of the screw classification. There are various types.

(1) Among the screw thread components of the composition, there are two types: integral screws and combination screws.

① An integral screw consists of the threaded part of a cylindrical screw with the same diameter as its outer diameter and the gradually decreasing outer diameter of the conical screw. In addition, cylindrical screws come in two types: one with a pitch that gradually narrows from the feeding section to the mixing section, and one with a constant screw groove and a wider screw flight width that gradually widens from the feeding section to the mixing section.

② A combined screw is one that has multiple distinct types of threaded units placed on a shaft with a long key. Or combined on a hexagonal mandrel to make a specific screw for extruding particular polymers. Most commonly, the combination screw is used for the fabrication of meshed co-rotating twin screws.

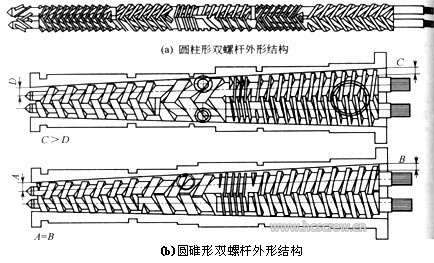

(2) Twin screws are classified into parallel twin screw with the same diameter and the axis of the two screws parallel after assembly. Or conical twin screw with progressively larger and smaller diameters and the axis of the two screws not parallel after assembly. The shapes of these two types twin extruder screw are shown in Figure 2.

3. Twin screw extruder barrel structure

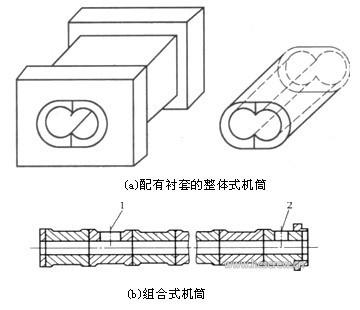

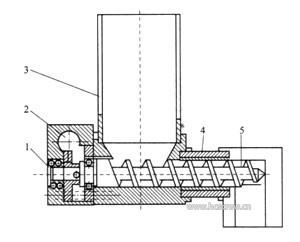

The twin screw extruder barrel structure is similar to that of a single screw extruder, with an integrated barrel and a segmented barrel. Figure 3 depicts the barrel construction.

1 —a vent port; 2 —feed port

Among the twin screw extruders, most of the meshing and conical twin screw extruders use integral barrels; only a few large extruders use segmented barrels, in order to facilitate machining and to save some of the more expensive alloy steel.

The majority of meshed co-rotating twin screw extruders use segmented barrels. A segmented barrel is divided into several equal-length sections. Barrels are made of several parts, some of which have feeding ports, some of which have vent ports, and some of which have additive ports, and the parts are assembled to create the twin screw combination barrel.

4. twin screw bearing axial force with bearing arrangement

The axial force generated by the twin screw in the extrusion work and the single screw in the extrusion work of the axial force is similar to or higher than the single screw extrusion axial force. Such a large axial force should require larger bearing specifications to bear, but, due to the twin screw work arrangement limiting the bearing arrangement space to bear the axial force of the screw, there is a variety of bearing arrangements. Only two common bearing arrangements are described here.

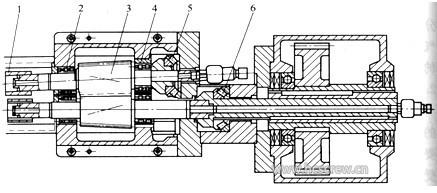

Figure 4 shows an example of the arrangement of a thrust bearing for a cylindrical twin screw. The two screws are arranged so that the bearings are staggered in order to accommodate the lack of space for the bearing arrangement. It has some limitations. Two screws in this bearing arrangement have equal axial forces. The bearings are subjected to equal axial forces and the axial displacement of the two screws is the same during operation, ensuring the normal engagement of the two screws.

1 —screw; 2 —drive shaft; 3, 6 —deep groove ball bearing; 4 —a resilient element; 5 —thrust roller bearing; 7 —gland

Figure 5 shows the arrangement of a thrust bearing for a conical twin screw. When the conical twin-screw is engaged in work, it has greater room at the end of the bearing region, resulting in a more compact bearing arrangement.

1 —a screw connection sleeve; 2, 4 —a cylindrical roller bearing; 3 —helical gear; 5, 6 -—conical roller bearing

5. Feeding device

According to the characteristics of the twin-screw extruder raw materials and the working conditions. The twin-screw extruder feeding device should be used to force metre the barrel material. Figure 6 shows the structure of the forced dosing device. This feeding device is like a single-screw extruder working independently. The screw that rotates and conveys raw materials is driven by a DC motor through the output shaft of a worm gear reducer. It is possible to adjust at any time the rotational speed of the screw conveying raw materials, the size of the conveying material, the twin-screw extruder’s twin-screw working speed, the barrel temperature, the melting pressure in the die, and the amount of material to form products with, according to the needs of the product with the amount of material. Generally, the threads on the filling rods are single-headed, but they can also be double-headed.

1 —Screw bearing; 2 —Worm gear reducer; 3 —Hopper; 4 —Extruder barrel; 5 —Extruder screw

If the raw material is in powder form, consider adding a spiral stirring mechanism to the hopper to prevent “bridging” the raw material in the hopper.

These are the components of a twin-screw extruder. These are wear-and-tear parts that can be changed. Brilliance Screws is a famous manufacturer of standard twin-screw barrels. Furthermore, customers may get high-quality extruder screw barrels as well as basic parts of extruder from us. Please contact us if you need to change these extruder parts or have concerns regarding the specific parameters of the machine parts you are using.

YOU MAY ALSO LIKE

| Conical Twin Screw Barrel ↗ Get latest & most competitive prices on China conical twin screw barrel, extruder barrels, extruder screw, bimetallic screw, SKD barrels. |

| Parallel Twin Screw Barrel ↗ Get latest good prices on China co-rotating twin screw barrel, parallel conical twin screw barrel. Advantages, comparisons, materials, models |

| Extrusion Twin Screw Barrel Accessories ↗ Buy extruder twin screw barrel accessories, parallel screw extruder parts screw barrel, gearbox, barrel heater bands, blowers, big nut, etc. |

People also ask

HUACHEN Screw is sold directly from our factory in China for export. Please let us know the type of extrusion screw barrel, or extrusion parts you are using, and the type of product you are producing. Our engineering staff will recommend the optimum anti-wear solution for your twin extrusion screw barrel and spare parts. We have a full stock of our top selling twin screw models and support 7 day delivery. Get the latest stock and pricing info from us.

Reception → screw barrel design checking and engineering service → prepare deposit → order manufacturing → quality control → finished product inspection → finished screw barrel checking → prepare balance payment → delivery → transportation

1. Business type: manufacturer, foreign trade company.

2. Origin: Zhoushan City, Zhejiang, China

3. Warranty: 12 months for fresh material.

4. International commercial terms: FOB, CFR, CIF, EXW

5. Scrcew barrel hs code: 8477900000

6. Terms of payment: T/T, L/C

7. Transport Package: AA Grade wooden case

You’ll get a reply from HUACHEN Screw within 1 hour or 24 hours.

TAGS

HUACHEN Screw Barrel Recent Post

- Boosting Efficiency and Quality: HUACHEN Screw Barrel’s Unmissable Showcase at HanoiPlas 2023

- Pipe Extrusion Operation: Best Practices for High-Quality Products

- Expert Maintenance Tips for Long-Lasting Bimetallic Alloy Screw Barrels

- Reviving Your Extruder: The Importance of Choosing the Right Screw Barrel Replacement

- Solutions to Common Production Problems for Rigid PVC Profiles and Pipes

- Customized Twin Screw Barrel with Internal Bore Grooves Sprayed with Bimetallic Alloy

- Troubleshooting Vent Flow Material Problems in PVC Profile Formation with Conical Twin Screw Extruders

- A Comprehensive Guide to Popular PVC Profiles and Their Production Methods

conical twin screw barrel extruder screw barrel extrusion screw barrel Foam sheet processing high speed screw barrel HUACHEN SCREW news injection screw barrel parallel twin screw barrel pa screw barrel pe making formula pe screw barrel plastic fiber processing plastic fibre screw barrel Plastic film making screw barrel plastic pipe processing Plastic profile processing Plastic raw material knowledge pp screw barrel PVC making formula pvc screw barrel related parts for screw barrel screw barrel engineering work screw barrel knowledge single screw barrel twin screw barrel

;