25 PVC Pipe And Other PVC Products Making Formulas

Date:2022-5-09 Author:hcscrew

There is a wide variety of PVC products, and common product classifications include PVC pipes, PVC sheets, PVC profiles, and so on. These include almost all the products needed in daily life. In order to let the plastic extruder user friends better understand, based on this, we have summarised some common PVC product formulas as the following. Please point out those who have opinions and improve them.

01 PVC drainage pipe making formula

1. PVC 100, heavy calcium 200, synthetic heavy calcium 50, compound lead salt stabilizer 5.6, stearic acid 1.8, paraffin wax 0.3, CPE10, titanium dioxide 3.6

2. PVC 100, 300 mesh heavy calcium 50, 80 mesh heavy calcium 150, stearic acid 0.8, paraffin 0.55, compound lead salt stabilizer 4~5, CPE 4

3. PVC 100, heavy calcium 125, light calcium 125, stabilizer 6.2, paraffin 1.5, stearic acid 1.3, titanium dioxide 4, CPE 10, PE wax 0.3, whitening agent 0.03

4. PVC 100, heavy calcium 250, light calcium 50, stearic acid 2.4, paraffin 2.6, CPE 6, lead salt stabilizer 5.0

5. PVC 100, stearic acid 1.0, paraffin 0.8, lead salt stabilizer 4.6, heavy calcium 200

6. PVC 100, light calcium 25, lead salt stabilizer 3.5, monoglycerin 1.1, PE wax 0.3, stearic acid 0.2, ACR (HF-801) 1.5, paraffin 0.35, titanium dioxide 1.5, ultramarine 0.02, whitening agent 0.02

02 PVC water supply pipe making formula

1. PVC 100, calcium-zinc compound stabilizer 3.5, light calcium 5, PE wax 0.15, stearic acid 0.2, CPE 3-6, ACR (HF-401) 1.0~2.0, titanium dioxide 2~4, appropriate amount of whitening agent. The same quality drainage pipe can use lead salt compound stabilizer

2. PVC100, compound lead salt stabilizer 2.4, paraffin wax 0.1, PE wax 0.13, stearic acid 0.3, monoglyceride 0.3, CPE 4, ACR (HF-801 or 100) 1.0, light calcium 20, titanium dioxide 1.0

03 PVC threading pipe making formula

1. PVC 100, light calcium 30, stabilizer 3.2, paraffin 0.6, stearic acid 0.4, titanium dioxide 1, CPE 6

2. PVC 100, light calcium 50, lead salt stabilizer 3.8, CPE 8, paraffin 0.3, stearic acid 0.8, titanium dioxide 0.8

04 Medical PVC plastic pipe making formula

PVC resin 50, tetraoctyl homophthalate 35.52, epoxidized soybean oil 1.89, stearic acid 0.15, Ca/Za environmental stabilizer 1.0, propanetriol 0.048, PE wax 0.1

05 PVC transparent hose making formula

PVC 100, DOTP 45, epoxidized soybean oil 5, stearic acid 0.4, PE wax 0.35, organic tin 1.5

06 PVC transparent regid pipe production formula

PVC 100, organic tin 1.4, MBS 5.0, ACR (HF-20) 0.6, internal lubricant 60 0.6, 74/70S 0.5

07 PVC construction template production formula

1. PVC (SG-8) 50, light calcium 25, compound lead salt stabilizer 2.3, white foaming agent 0.45, foaming agent AC 0.3, wood powder 10, PVC recycled material 20, foaming regulator (HF-80) 4, CPE 2, stearic acid 0.35, PE wax 0.25

2. PVC 75, light calcium 35, recycle material 50, foam board waste 20, lead salt compound stabilizer 3.6, foam regulator (HF-533) 9.5, internal lubricant 60 0.4, PE wax 0.55, OA6 or 316A 0.5, AC foamer 0.3, white foamer NC 0.8

08 PVC pipe fittings production formula

1. PVC (SG-7) 100, heat stabilizer 3.5, DOP 3.0, ACR (HF-100 or 200) 1.5, PE wax 0.6, internal lubricant (stearic acid or high quality monoglycerin) 1.2, light calcium carbonate 25

2. PVC (SG-7) 100, heat stabilizer 3.8, DOP 3.0, ACR (HF-100 or 200) 2.0, polyethylene wax 0.35, paraffin wax 0.3, stearic acid 0.3, monoglyceride 1.2, light calcium carbonate 35, ultramarine 0.02, fluorescent whitening agent 0.02

09 PVC wire box production formula

PVC100, light calcium 30, compound lead salt stabilizer 3.6, ACR 2.0, DOP3, stearic acid 1.0, paraffin 0.3, PE wax 0.35, whitening agent 0.02, titanium dioxide 1.6

10 PVC high filling WPC sheet production formula

PVC100, lead salt compound stabilizer 5.6, foam regulator (HF-100) 11, monoglycerin 4.0, PE wax 1.2, stearic acid 0.5, wood flour 30, calcium powder 200, AC foamer 2.0, suitable amount of paint, return material 60

11 PVC wall panels production formula

1. PVC 100, heavy calcium 220, PE wax 1.2, stearic acid 2.0, DOP 4.0, CPE 8.0, lead salt compound stabilizer 5.2, titanium dioxide 3.0, fluorescent whitening agent 0.02

2. PVC 100, heavy calcium 200, lead salt compound stabilizer 5.6, paraffin 1.2, stearic acid 2.4, DOP 3.0, CPE 8.0, titanium dioxide 3.0, fluorescent whitening agent 0.03

3. PVC 100, heavy calcium 250, lead salt compound stabilizer 5.6, paraffin 1.4, stearic acid 2.4, DOP 3.0, CPE 8.0, grinding powder 40

12 PVC calendered floor leather production formula

PVC100, heavy calcium 60, lead salt compound stabilizer 2.5, PE wax 0.25, ACR (HF-100) 1~2, stearic acid 0.3, DOP 32, titanium dioxide 1.0, fluorescent whitening agent 0.05, ultramarine 0.18

13 PVC floor cloth production formula

PVC 50, rare earth stabilizer 2.0, paraffin 0.6, magnesium hydroxide 16, light calcium carbonate 15, DOP 35, chlorinated paraffin 15, stearic acid 0.6, color powder suitable amount

14 PVC flooring substrate production formula

1. PVC 75, light calcium 85, calcium-zinc compound stabilizer 4.2, foam regulator (HF-80) 8, AC foaming agent 0.25, white heat-absorbing foaming agent 0.6, 316A 0.4, internal lubricant 60 0.75, PE wax 0.55, return material 40

2. PVC 75, light calcium 75, calcium-zinc compound stabilizer 4.0, foam regulator (HF-80) 7.2, AC foaming agent 0.25, white heat-absorbing foaming agent 0.6, 316A 0.35, internal lubricant 60 0.70, PE wax 0.5, return material 30

15 PVC resin tile production formula

1. Plastic grinding material 125, light calcium 25, stabilizer 3.0, CPE 5, stearic acid 0.5, PE wax 0.5

2. PVC 100, lead salt compound stabilizer 4.0, CPE 5, stearic acid 1.4, paraffin wax 0.4, PE wax 0.5

16 PVC profile production formula

1. PVC (SG-5) 100, lead compound 4, stearic acid 0.3, PE wax 0.25, ACR (HF-801S or 100) 2, CPE (35%) 10, active light calcium 15, titanium dioxide 2.5

2. 100 parts of PVC (SG-5), 4.2 parts of calcium and zinc stabilizer, 0.3 parts of stearic acid, 0.3 parts of paraffin wax, 0.3 parts of monoglycerin, 2 parts of ACR (HF-801S or 100), 10 parts of CPE (35%), 40 parts of light calcium, 4.5 parts of titanium dioxide, 0.02 parts of ultramarine, whitener 0.012.

17 PVC heat-shrinkable film production formula

PVC 50, calcium stearate 0.3, stearic acid 0.25, ACR (HF-20/175) 0.3-0.8, nano calcium 0.3, paraffin 0.25, DOP 2.5, soybean oil 2, barium-chromium-zinc stabilizer 1.6 (or organic tin 1.3), whitener 0.005

18 PVC transparent sheet production formula

PVC (SG-7/8) 100, organotin 0.8-1.2, ACR (HF-20) 0.8, MBS 2-4, 0K-60 0.8, 70S 0.5, fluorescent whitening agent 0.002, ultramarine 0.001

19 PVC crust foam board production formula

1. PVC (700) 100, lead salt compound stabilizer 4.4, light calcium 60, foam regulator (HF-90) 10.5, AC 0.65, NC 1.5, 316A 0.6, PE wax 0.4, 6A 0.2, internal lubricant 60 0.8, titanium dioxide 2.0, whitening agent 0.04, ultramarine 0.03, grinding material 60

2. PVC 75, lead salt stabilizer 3.3, AC 0.4, white foam 1.1, internal lubricant 60 0.7, 316A 0.48, PE wax 0.35, 6A 0.2, foam regulator (HF-922/901) 8.5, light calcium 55~60, back to material 40

20 PVC free foam board production formula

1. PVC (700) 100, lead salt compound stabilizer 4.0, light calcium 40, foam regulator (HF-418/80) 10, AC 0.5, 316A 0.54, PE wax 0.36, 6A 0.2, internal lubricant 60 0.45, titanium dioxide 2.0, whitening agent 0.04, ultramarine 0.03, grinding material 40~50

2. PVC (700) 100, lead salt compound stabilizer 4.0, light calcium 40, foam regulator (HF-418/80) 8~10, AC 0.38, 316A 0.62, PE wax 0.3, 6A 0.3, internal lubricant 60 0.6, titanium dioxide 4.0, whitening agent 0.08, ultramarine 0.03, grinding powder 30~60

21 PVC foam stair handrail production formula

Foamed template waste 100, light calcium 12.5, stabilizer 0.8, stearic acid 0.5, PE wax 0.2, AC 0.25, white foam 0.5, foam regulator (HF-80/533) 7, CPE 3

22 WPC wall panel production formula

1. PVC-8 25, small pipe material 100, light calcium 50, wood powder 7, CPE 5, back material 25, lead salt stabilizer 1.8, foam regulator (HF-100/418/80) 5, AC 0.35, white foam 0.6, PE wax 0.5, stearic acid 0.6, suitable amount of paint

2. PVC-8 50, light calcium 50, wood flour 5, CPE 3, recycle 30, lead salt stabilizer 3.0, foam regulator (HF-100/418/80) 6, AC 0.55, white foam 0.5, PE wax 0.5, stearic acid 0.6, suitable amount of paint

3. Small tube material 75, light calcium 50, back material 50, wood flour 8, PVC 12.5, stabilizer 2.0, foam regulator (HF-100/418/80) 6~8, AC 0.6, white foam 1.0, PE wax 0.3, stearic acid 0.5, suitable amount of paint

4. PVC-8 75, light calcium 80, wood powder 5, CPE 2, back to 25, lead salt stabilizer 4.3, foam regulator (HF-100/418/80) 6~8, AC 0.6, white foam 0.9, PE wax 0.6, stearic acid 0.8~1.2, suitable amount of paint

23 PVC wood plastic door strip production formula

1. PVC 25, small pipe material 108, heavy calcium 75, stabilizer 2.5, CPE 4, regulator (HF-100) 8.0, AC 0.8, PE wax 0.2, stearic acid 0.2

2. PVC 25, light calcium 50, small tube material 50-75, back material 25, wood powder 8, PE wax 0.3, stearic acid 0.4, lead salt stabilizer 1.8, AC 0.65, foam regulator (HF-100) 3.5

24 PVC foam shoe sole production formula

1. PVC 100, DOP 80~85, light calcium 60~65, AC 0.5~0.6, foam regulator (HF-100/200) about 2.0, lead salt compound stabilizer 3.8, PE wax 0.6, stearic acid 1.0, color powder suitable amount

2. PVC 100, DOP 90, light calcium 70, AC 0.8, foam regulator (HF-100/200) about 2.0, lead salt compound stabilizer 4.0, PE wax 0.8, stearic acid 1.2, color powder suitable amount

3. PVC 100, DIBP 85, light calcium 60, AC 0.5, foam regulator (HF-100/200) about 2.0, calcium and zinc compound stabilizer 4.0, PE wax 0.2, stearic acid 0.3, color powder suitable amount

25 PVC edgebanding production formula

PVC powder: SG-5 is used for rigid 0.6-3mm thick edgebanding with low oil absorption; SG-3 type is used for rigid 0.4-0.6mm edgebanding with good oil absorption and good toughness.

| 1:1 formulation | 2:1 formulation | 3:2 formulation | |

|---|---|---|---|

| PVC | 50 | 50 | 50 |

| Heavy calcium | 50 | 25 | 33 |

| DOP | 2 | 2 | 2 |

| Stabilizer | 2.5 | 1.9 | 2.1 |

| Stearic acid | 0.6 | 0.4 | 0.5 |

| PE wax | 0.45 | 0.3 | 0.4 |

| CPE | 3 | 2 | 2.5 |

| ACR(HF-801) | 0.5~1.0 | 0.5 | 0.5 |

Summary

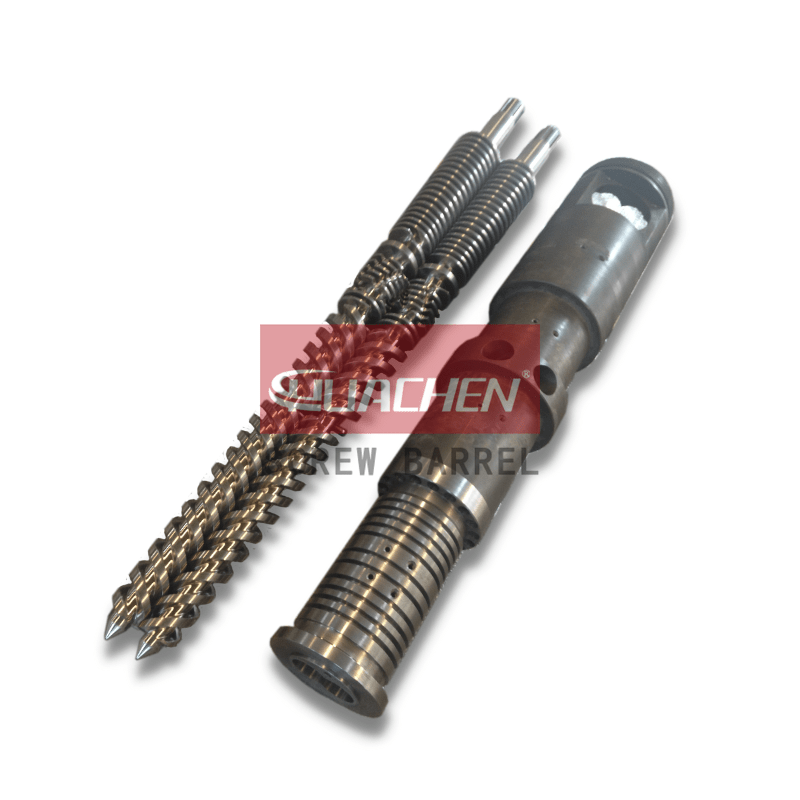

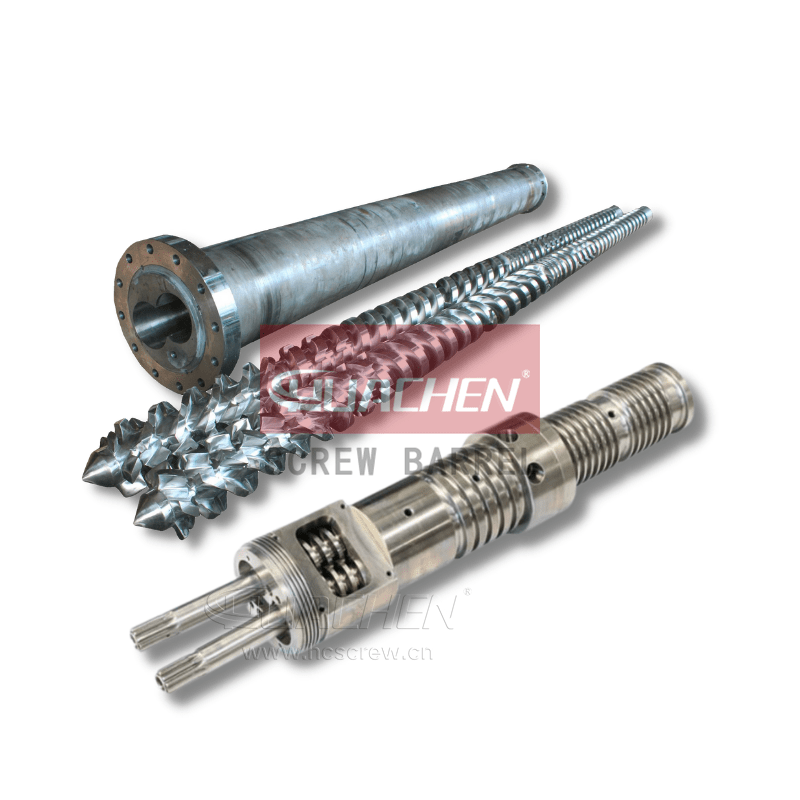

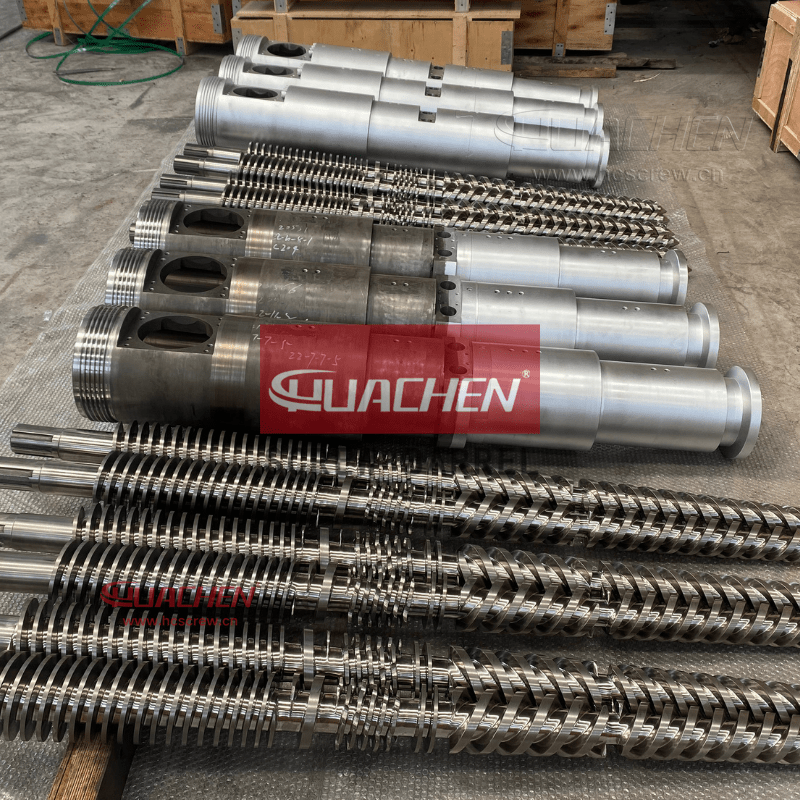

These are 25 practical formulas for extruding PVC products. High quality PVC products production process, with excellent extruder parts screw barrel design and optimized performance, can provide our customers with stable and efficient PVC products. If you have more questions about PVC products production formulas and PVC extrusion problems, welcome to quote or contact us HUACHEN Screw Barrel Factory to get the latest information.

YOU MAY ALSO LIKE

| PVC Screw Barrel ↗ Get details and latest price of PVC screw barrel, high output, PVC single, parallel, conical twin screws, advantages, applications at HUACHEN… |

| RPVC, CPVC, UPVC Screw Barrel ↗ Get details and latest price of RPVC, CPVC, UPVC screw barrel, high-speed design, better anti-wear and anti-corrosion screw barrel at HUACHEN… |

More posts about PVC pipes

HUACHEN Screw Barrel recent posts

- Boosting Efficiency and Quality: HUACHEN Screw Barrel’s Unmissable Showcase at HanoiPlas 2023

- Pipe Extrusion Operation: Best Practices for High-Quality Products

- Expert Maintenance Tips for Long-Lasting Bimetallic Alloy Screw Barrels

- Reviving Your Extruder: The Importance of Choosing the Right Screw Barrel Replacement

- Solutions to Common Production Problems for Rigid PVC Profiles and Pipes

- Customized Twin Screw Barrel with Internal Bore Grooves Sprayed with Bimetallic Alloy

- Troubleshooting Vent Flow Material Problems in PVC Profile Formation with Conical Twin Screw Extruders

- A Comprehensive Guide to Popular PVC Profiles and Their Production Methods

conical twin screw barrel extruder screw barrel extrusion screw barrel Foam sheet processing high speed screw barrel HUACHEN SCREW news injection screw barrel parallel twin screw barrel pa screw barrel pe making formula pe screw barrel plastic fiber processing plastic fibre screw barrel Plastic film making screw barrel plastic pipe processing Plastic profile processing Plastic raw material knowledge pp screw barrel PVC making formula pvc screw barrel related parts for screw barrel screw barrel engineering work screw barrel knowledge single screw barrel twin screw barrel

;