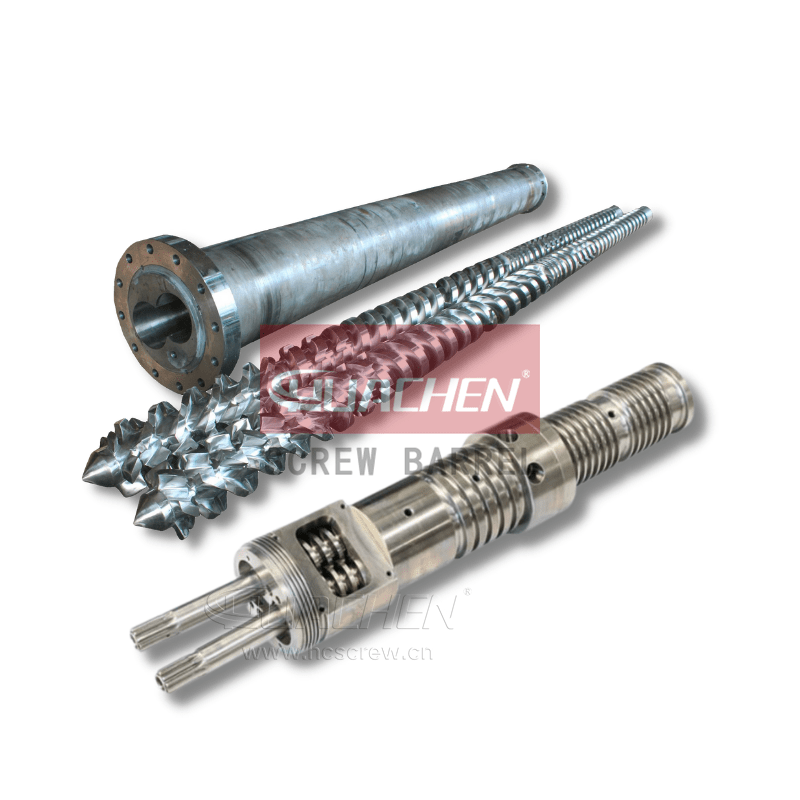

PVC Screw Barrel

● Min. Order (MOQ): 1 Set

● UPVC, CPVC, RPVC

● Pipe, profile, sheet extrusion

● Compound pelletizing, recycling pelletizing

● Injection moulding

● Cable, wire extrusion

● blown film

You Need Better PVC Screw Barrel at Good Price!

- Product Detail

HUACHEN Screw has been a leading PVC Screw Barrel manufacturer in Zhoushan Jintang since 2005. With many years of experience in the design and processing of plastic machinery accessories, HUACHEN Screw can provide its customers with a wide range of services including made-to-order screw barrels, rebuilding, modification, and upgrade. Our company has also successfully exported and supplied screw barrels to customers worldwide.

>> Learn More About Our Company

PVC Screw Barrel

HUACHEN provides the following types of PVC screws.

1. equidistant unequal-depth tapering single screw designs, and equidistant unequal-depth tapering single screw designs

2. Counter-rotating parallel and conical twin screw barrel.

3. Co-rotating Parallel and conical twin screw barrel.

At present, over 90% of PVC production is carried out with twin screw barrels (parallel and conical). To meet the requirements of different regions and countries, we have fine-tuned our PVC screw barrels.

PVC screws design principles

1. The design of PVC screw barrel should have a low shear to prevent overheating.

2. Corrosion-resistant screws and barrels are essential.

3. Injection moulding requires strict control.

>>Learn More About PVC screw barrel designs

Rigid PVC profiles, PVC pipes screw barrel

Conical twin screw extruders are widely used for forming rigid PVC products like PVC profiles and pipes.

The parallel twin screw is 60% longer than the conical twin screw in the feeding section, but its heat transfer area is 45% smaller. In contrast to parallel screws, conical twin screws are faster at moving materials between them. Therefore, the conical screw generates more shear heat than the parallel screw. Conical twin-screw filling sections have a better plasticizing effect on materials than parallel screws because of their structural design.

Additionally, the volume of the conical twin-screw screw groove decreases during the conveying process, while the squeezing effect increases. As a result, the conical screw provides a higher energy conversion rate, resulting in a better preplasticization effect. In the conical twin-screw metering section, the screw diameter is smaller and the material is less likely to be sheared. In this section of the screw structure, there is less shear heat, which is perfect for plasticizing PVC.

PVC pelletizing screw barrel.

PVC compound pelletizing commonly uses counter-rotating parallel twin-screw and conical twin screw machines. Co-rotating parallel twin screws are commonly used in PVC modification. Pelletizing with single screws can be done with low yield and quality requirements.

PVC injection moulding screw barrel

As injection moulding plastics, PVC can be split into granules and powders and is highly viscous, very corrosive, and easily decomposed.

Screws are characterized by two features: chrome-plated surfaces and no dividing rings or medium. In screw construction, it is necessary to ensure good plasticisation, low shear heat generation, and corrosion resistance against acids. The screw and dispensing head can either be integrated or separated.

Application of PVC screw barrel

1. PVC single screw for cable wire extrusion machine

2. PVC single screw for recycling machine

3. PVC single screw for garden pipe and tube extrusion

4. PVC single screw for blown film machine

5. PVC Twin screw for RPVC pipe extrusion (All standards ready stock)

6. UPVC Twin screw barrel set for pipe manufacturing

7. UPVC Twin screw barrel set for Profile manufacturing

8. CPVC Twin parallel screw barrel set for pipe manufacturing

9. CPVC Twin conical screw barrel set for pipe manufacturing

10. PVC Foam sheet manufacturing

11. PVC Injection moulding machine screw barrel

Specifications

1. Based materials: Premium 38CrMoAlA (UNS K24065, SACM645, 41CrAlMo7-10),SKD11, SKD61

2. Plasma nitriding surface hardness: HV 1000-1100

3. Plasma nitriding depth: ≥ 0.7 mm

4. Nitriding fragility: less than Grade I.

5. Surface Roughness: Ra 0.4 μm

6. Screw Linearity: ≤ 0.015mm

7. Alloy depth: 4-6 mm

8. Alloy surface hardness: ≥ HRC 61

>> Learn more about our PVC screw barrel parameters

Our PVC screw barrel ultimate solution for abrasion and wear

1. Alloy steel of high strength, tempered and nitride.

2. Overlay of nickel-based and molybdenum-based alloys on vulnerable screw parts with a thickness of 1 to 1.5 mm. Effectively provide 1.5 times longer service life.

3. hard chrome plating process.

4. bimetallic layer processing on barrel input opening section available.

5. Grooved feed barrel structure available.

6. SKD sleeve fitted barrel available

>>Learn more about our bimetallic screw barrel treatments

Production time

Complete set of PVC screw barrel within 28 days depending on the complexity of the part.

We have a wide selection at good prices to help you get creative. The PVC Screw Barrel for Sale is guaranteed to be of high quality. We are the China Origin Factory of PVC screw barrels. If you have any questions, please feel free to contact us.