What Is A Vented Extruder Screw?

Date:2022-5-13 Author:hcscrew

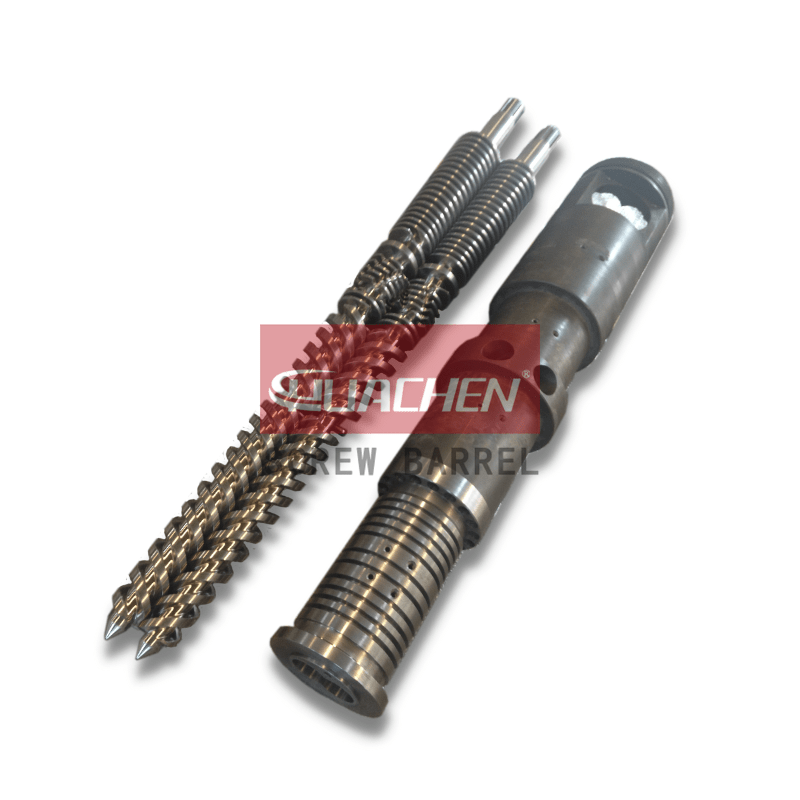

A Vented Extruder screw is also known as a degassing screw or vented screw for short. For single screw extruders, there are vented and non-vented extruders.

01 Why Do We Use a Vented Extruder Screw?

PO, PA, PC, PET, and other polymer raw materials easily absorb water in the process of storage and placement. Plastic producers may add a lot of filler to it in order to save raw materials. The fillers are plastic because they contain calcium carbonate, wood powder, etc., and they produce a lot of gas, like PVC. Such as volatile materials. Plasticisation occurs in a barrel where wet and volatiles cannot be exhausted, resulting in defects in the product. In this case, we can use the vented screw design.

The vented extruder screw continuously extracts volatiles from the polymer. This type of extruder has one or more vent holes in the barrel to allow volatiles to escape. Extruding water out of monomers, oligomers, polycondensation reactants (such as water), volatile polymer ingredients, and hydrophilic polymers (ABS, PA, PC, etc.) is possible with the vented extruder.

02 What Is A Typical Vented Extruder Screw Structure?

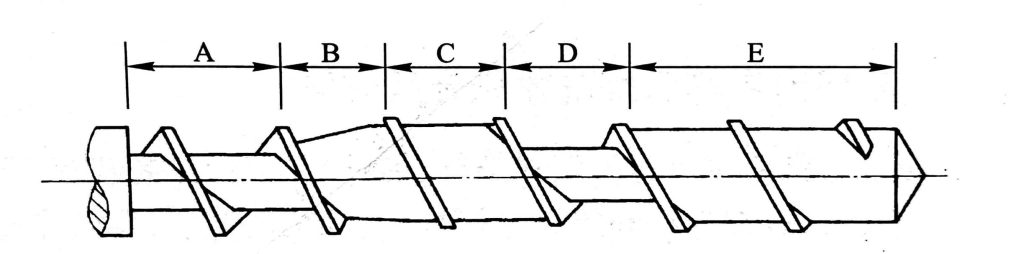

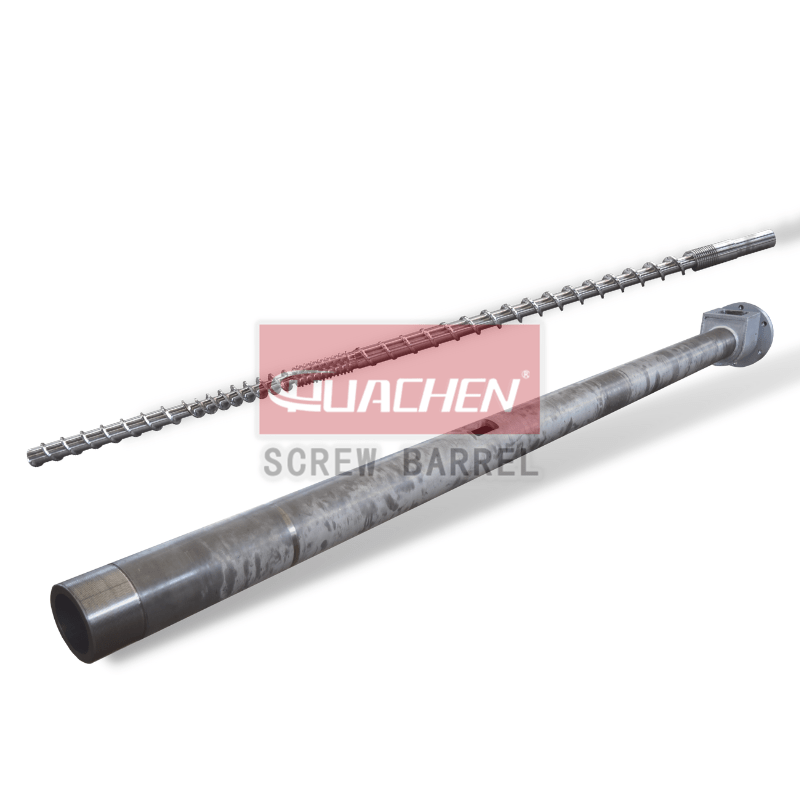

The above diagram shows a typical two-stage vented extruder screw with at least five functional segments of different geometries. Three sections are the charging section, the compression section, and the metering section. They are the same as those of a general-purpose screw. There is a metering section, a venting and decompression section, and a rapid compression and pump-out section.

There are two basic functional requirements for effective venting.

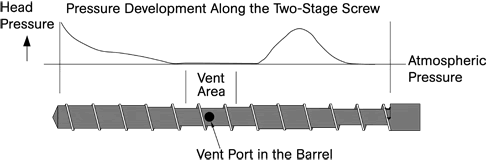

1) the polymer pressure under the vent is zero.

It stops the polymer melt from escaping through the vent. In the case of an empty screw groove, no pressure can develop. At least in the direction of the screw grooves. In order to achieve partial filling, the depth of the venting section must be much wider than the depth of the metering section. At least three times greater. The conveying capacity of the pumping section must be greater than the conveying capacity of the metering section. If the conveying capacity of the pumping section is not sufficient, the polymer melt will stagnate in the pumping section. Then escape through the venting hole. Therefore, the ratio of pumping section screw groove depth and metering section depth is generally taken as 1.5 ~ 2.0.

2) the polymer in the venting hole is completely melted.

The seal between the venting hole and the filling port is not strong enough. It is not possible to meet vacuum requirements, which affect the release of volatiles. Diffusion controls the vent on the extruder. The diffusion coefficient is quite dependent on the temperature. If the polymer temperature is below the melting point, diffusion takes place at a very low rate. In order to increase the diffusion rate and thus also the venting efficiency, the polymer temperature should be above the melting point. Since the polymer should be in a molten state, the diffusion coefficient increases as the melt temperature increases.

Molten polymers can renew their surfaces, which speeds up the venting process. The degree of surface renewal plays an imperative role in screw design. And a multi-threaded, large-pitch venting section will improve exhaust efficiency. In order to achieve high venting efficiency, it should enter the metering section at a high temperature. Then it is completely melted.

Summary

Simply put, every extruder screw can be converted to a venting extruder screw. It is actually quite simple to implement this in venting.

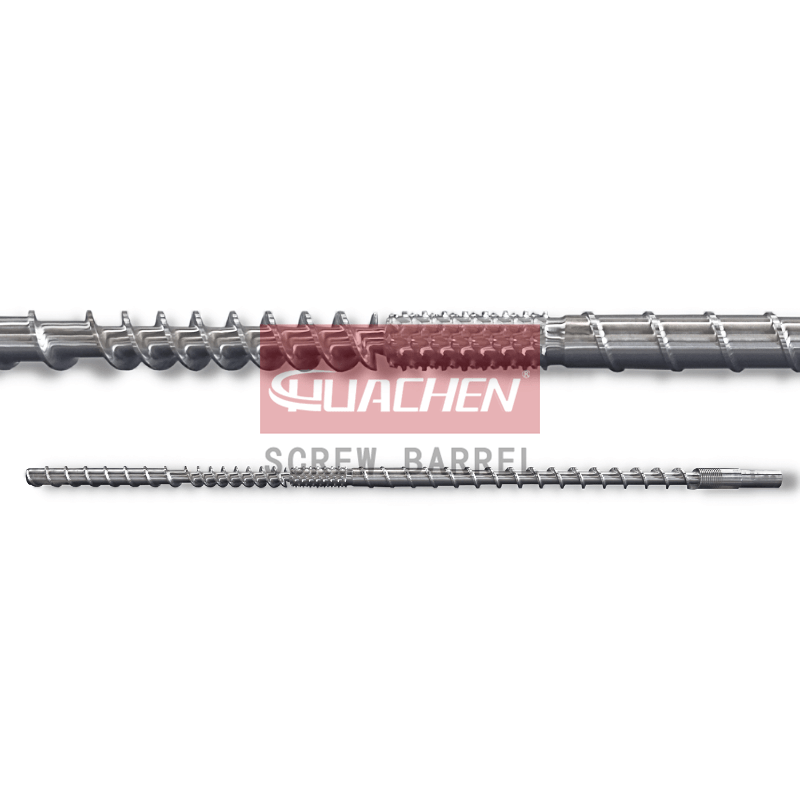

To summarise, what is a vented extruder screw? A reverse threaded element (or a reverse pinch block, or any kind of pressure element) + a large lead threaded element. At the same time, the extruder barrel’s large threaded element also contains a venting port or a forced venting port with a negative vacuum pressure. The principle is to suddenly expand the surface of the melt while allowing the melt pressure to drop sharply. In this way, the venting function can be realised.

Of course, it is common to use the above method only to vent. The cavity in the melt causes only a small number of air bubbles or moisture. Some specific modifications are needed for reactive extrusion, but the principle is the same.

YOU MAY ALSO LIKE

| Vented Screw ↗ Get details and latest price of the vented extruder screw, good for high output, venting screws structure, advantages, applications at HUACHEN… |

| Vented Screw Barrel ↗ Get details and latest price of vented extruder screw barrel, high output, venting screw barrel, advantages, applications at HUACHEN… |

| PET Recycled Polyester Staple Fibre Screw Barrel ↗ Get details and latest price of PET recycled polyester staple fibre screw barrel, heavy duty RPSF screw barrels for PET recycling fibre… |

| Plastic Recycle Pellets Granulation Machine Screw Barrel ↗ Details and price of heavy duty plastic recycle pellets granulation machine screw barrel, find upgraded pelletizing screw barrel at HUACHEN |

People also ask

HUACHEN Screw is sold directly from our factory in China for export. Please let us know the type of vented screw barrel you are using, the type of product you are producing, and the amount of filling. Our engineering staff will recommend the optimum anti-wear solution for your venting extruder screw barrel. Get the latest stock and pricing info from us.

Reception → screw barrel design checking and engineering service → prepare deposit → order manufacturing → quality control → finished product inspection → finished screw barrel checking → prepare balance payment → delivery → transportation

1. Business type: manufacturer, foreign trade company.

2. Origin: Zhoushan City, Zhejiang, China

3. Warranty: 12 months for fresh material.

4. International commercial terms: FOB, CFR, CIF, EXW

5. Scrcew barrel hs code: 8477900000

6. Terms of payment: T/T, L/C

7. Transport Package: AA Grade wooden case

You’ll get a reply from HUACHEN Screw within 1 hour or 24 hours.

About us

HUACHEN Screw has been an outstanding producer of plastic recycle pellets granulation machine screw barrels in Zhoushan Jintang since 1993. With many years of experience in designing and processing plastic machinery replacement parts, HUACHEN Screw can provide its customers with a wide range of services, including drawing rebuilding, design, modification, and customization. Our company has also successfully exported and supplied screw barrels to customers worldwide.

Request a quote or contact us to learn more about vented extruder screw barrels.

Tags

HUACHEN Screw Barrel Recent Post

- Boosting Efficiency and Quality: HUACHEN Screw Barrel’s Unmissable Showcase at HanoiPlas 2023

- Pipe Extrusion Operation: Best Practices for High-Quality Products

- Expert Maintenance Tips for Long-Lasting Bimetallic Alloy Screw Barrels

- Reviving Your Extruder: The Importance of Choosing the Right Screw Barrel Replacement

- Solutions to Common Production Problems for Rigid PVC Profiles and Pipes

- Customized Twin Screw Barrel with Internal Bore Grooves Sprayed with Bimetallic Alloy

- Troubleshooting Vent Flow Material Problems in PVC Profile Formation with Conical Twin Screw Extruders

- A Comprehensive Guide to Popular PVC Profiles and Their Production Methods

conical twin screw barrel extruder screw barrel extrusion screw barrel Foam sheet processing high speed screw barrel HUACHEN SCREW news injection screw barrel parallel twin screw barrel pa screw barrel pe making formula pe screw barrel plastic fiber processing plastic fibre screw barrel Plastic film making screw barrel plastic pipe processing Plastic profile processing Plastic raw material knowledge pp screw barrel PVC making formula pvc screw barrel related parts for screw barrel screw barrel engineering work screw barrel knowledge single screw barrel twin screw barrel

;