Bimetallic Alloy Screw Barrel

● Min. Order (MOQ): Set

● Pipe extrusion ● Sheet extrusion

● Profile extrusion ● Recycling extrusion

● Compounding extrusion ● Cable / wire extrusion

● Blown film / Lamination ● Colour liner / Coating extrusion

● Nonwoven fabric extrusion ● Monofilament / staple fibre extrusion

● Cast film ● Blow Moulding ● Injection Moulding

You Need Better Bimetallic Alloy Screw Barrel at Good Price!

- Product Detail

HUACHEN Screw has been a leading bimetallic alloy screw barrel manufacturer in Zhoushan Jintang since 2005. With many years of experience in the design and processing of plastic machinery extrusion parts, HUACHEN Screw can provide its customers with a wide range of services including screw barrel design, rebuilding, modification, and upgrade. Our company has also successfully exported and supplied screw barrels to customers worldwide.

>>Learn more about our company

Bimetallic Alloy Screw Barrel Advantages

1. Corrosion resisting.

Plastic materials such as fluorine, PVC, ABS, additive GF, etc. When the extrusion temperature rises, corrosive gases are released, damaging your screw and barrel. Nitrided screw barrels, on the other hand, cannot be used for long periods of time. Alternatively, a bimetallic screw barrel resists corrosion, resulting in longer service life. Our bimetallic alloy screw barrels are backed by a one-year warranty, but our customers use them for many years.

2. Wear resisting

Some materials are processed with the addition of filler materials. Mixing filler materials such as Caco3, stone dust, wood powder, foam, or recycled material with these filler materials can easily wear out the screw barrels. Normal nitrided screw barrels will not last much longer when extruding these filler plastics and may need to be replaced after half a year. Our upgraded bimetallic screw barrels are guaranteed for one year if you use them in this situation. With the same processing environment and formulation ratios, our customers have reported that they can last several years longer.

>>Learn more about bimetallic screw vs nitrided screw

Our bimetallic alloy standard

1. Substrate treatment grade: 38CrMoAlA + nitriding 96-120 hours

2. Bimetallic grade: 38CrMoAlA + bimetallic alloy

3. Bimetallic alloys: nickel-based alloys, cobalt-based alloys, molybdenum-based alloys, Cobalt tungsten carbide hard alloys, ceramic alloys.

4. HC-A grade: Tungsten carbide 40%

5. HC-B grade: Tungsten carbide 25%

6. HC-C grade: Tungsten carbide 15%

7. Chrome plating screw

8. Ceramic alloy screw

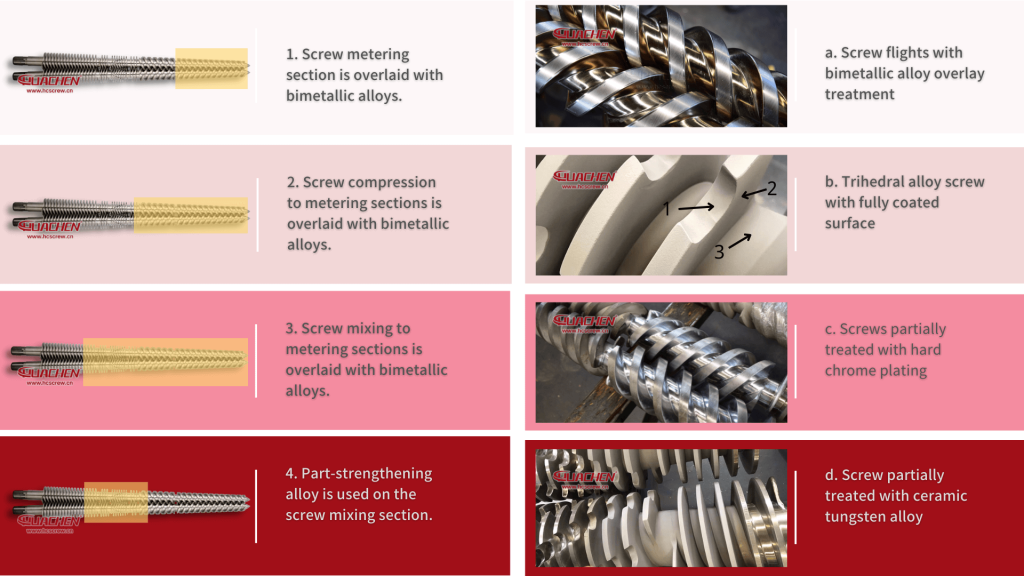

Bimetallic alloy screw come in two types:

Bimetallic can also be divided into two types, as shown in the above picture:

Type 1 – Screw flights welded with bimetallic alloy, this is very common in the market today. We recommend you choose this type if your plastic material is not quite as problematic since it is more cost-effective.

Type 2 – Coating the whole screw with bimetallic alloy. This is a new technology these days. The advantage: Working life is much longer than type 1. The disadvantage: Price is also considerably higher than type 1.

>>Learn more about what is bimetallic screw barrel

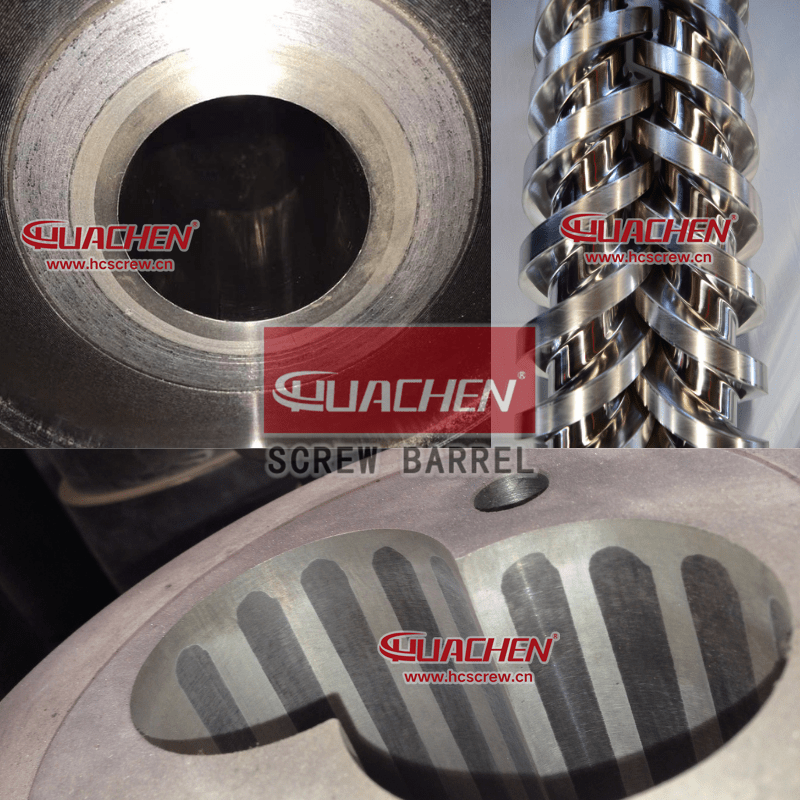

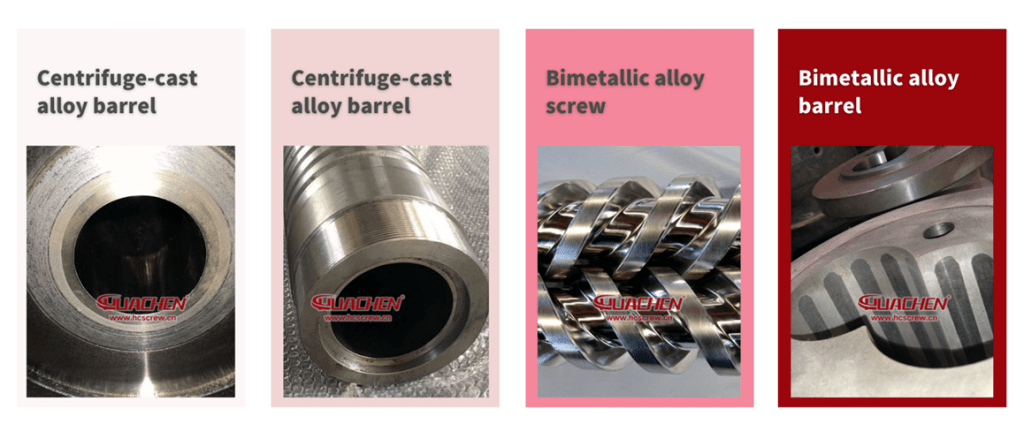

Bimetallic alloy barrel come in two types

For your bimetallic alloy barrel, you have two options:

Type – 1, grooved and coated bimetallic alloy barrel. In areas prone to wear, we draw longitudinal grooves in the bore of the barrel. We spray a bimetallic alloy compound into the grooves, then polish the bore smoothly.

Type – 2. centrifuge-cast alloy barrel. We use a centrifugally cast alloy base that is resistant to wear and corrosion, and reinforces its durability with centrifugal casting.

Application of bimetallic alloy screw barrel

4. Injection moulding screw barrel

Materials

1. Based materials: Premium 38CrMoAlA

2. Plasma nitriding surface hardness: HV 1000-1100

3. Plasma nitriding depth: ≥ 0.7 mm

4. Nitriding fragility: less than Grade I.

5. Surface Roughness: Ra 0.4 μm

6. Screw Linearity: ≤ 0.015mm

7. Alloy depth: 2-4 mm

8. Alloy surface hardness: ≥ HRC 61

>>Learn more about our bimetallic screw barrel parameters

Production time

Ready stock model within 7 days, and custom made model within 35 days depending on the complexity of the part.

We have a wide selection at good prices to help you get creative. The bimetallic alloy screw barrel for Sale is guaranteed high quality. We are the China Origin Factory of bimetallic alloy screw barrels. If you have any questions, please feel free to contact us.