Is Your Plastic Product Requiring Nitrided Or Bimetallic Screw?

Date:2022-8-04 Author:hcscrew

Nitrided screws are screws that have been hardened by nitriding. Nitriding is a process that adds nitrogen atoms to the surface of metal parts. Compared to untreated steel, it’s stronger, more durable, and resists corrosion better. Bimetallic screws are made from two different metals that react differently when heated. These are used in applications where high strength and corrosion resistance are needed.

It is common for global screw barrel buyers to encounter a situation like this when purchasing in China.

Screw barrel manufacturers in China prefer to recommend using bimetallic screw barrel rather than nitrided screw barrel.

Why are nitrided screws so popular? What are bimetallic screws?

The HUACHEN Screw Barrel will explain what a nitrided screw is and introduce some other common bimetallic screw treatment methods.

01: What is nitrided screw?

Nitrided screws are manufactured from nitrided steel. The most basic screw materials and treatment methods. In many countries today, nitrided steel screws are still in use because of their economical nature.

There are two common nitrided steels used in West Germany: 8550 (34CrAlNi7) and 8519 (31CrMoV9). These steels are mostly medium carbon steels containing 0.30-0.40% carbon, but they also contain Si, Mn, Cr, Ni, Mo, V, Al, and other alloying elements. 42CrMo4 steel and flame-hardened steel make up about 80% of screws in the USA. For screws with high wear resistance, the remaining 20% incorporate nitrided steel and bimetallic materials. In Japan, small and medium screws frequently use nitrided steel screws, while medium carbon steel screws are flame hardened.

In China, most screws are made from nitrided steel, 38CrMoAlA, and some plastics factories also use screw barrels made from 40Cr or 45 gauge steel.

02: Nitrided screws no longer have the advantages it once did

Since the speed of the extruder screw has increased in recent years, the pressure inside the barrel has increased. The extrusion of plastics uses a large amount of high-strength fillers. Thus, nitrided steel screws and barrels are insufficient for processing plastics today.

This failure is mainly due to the fact that, in general, screw and barrel nitride layers are around 0.5 mm thick. Furthermore, the nitrided steel matrix has a low hardness, only around HV 280. As the nitrided layer on the screw surface wears away, the screw loses its wear resistance. If nitriding isn’t done correctly, the nitrided layer becomes brittle and flakes off easily. As a result, nitrided screws lose their wear resistance. Due to the substrate’s low hardness, high pressure indents the thin nitrided layer. Moreover, it can destroy the screw.

Nitrided steel is generally insufficiently corrosion resistant, despite being enhanced by the nitriding process. It is especially true when extruding rigid PVC and certain engineering plastics.

03: Bimetallic screw treatment methods

Based on the above, we can assume that nitrided steel is no longer an advanced material for screw barrels. To meet the requirements of extrusion production, better materials and processes have been sought. The global screw barrel industry is currently developing a bimetallic screw treatment process, specifically in the following directions.

1. Hard chrome plating

The chemical treatment method used here is relatively old. The screw material used for hard chrome plating can be 40Cr or 45 steel. In addition to having a good surface finish and corrosion resistance, the hard chrome plated screw is also more resistant to wear. Nevertheless, this approach to chrome plating is very demanding; the plating is too thin, too thick, and easy to flake. Currently, the general rule is 0.05-0.1mm. Metal matrix bonding and plating must be very strong. It is still possible that the crater and chromium layer peeling away between the two poles will constitute a chemical battery. As a result, the screw corrodes more quickly.

2. Brittle hardening or surface flame hardening

Surface hardening is a cheap and convenient treatment method. A hardened part can reach HRC55, with a quenching depth of 2 – 3mm. Flame hardening screws can be made from 40Cr or 45 steel, so they are very economical for large screws. In order to strengthen the surface of the screw, it can be heated to 815°C using fuels such as acetylene, propane, nitrogen, water gas, etc. Using high frequency quenching, the quenching frequency should be greater than 4000 Hz, followed by water bath or spray quenching.

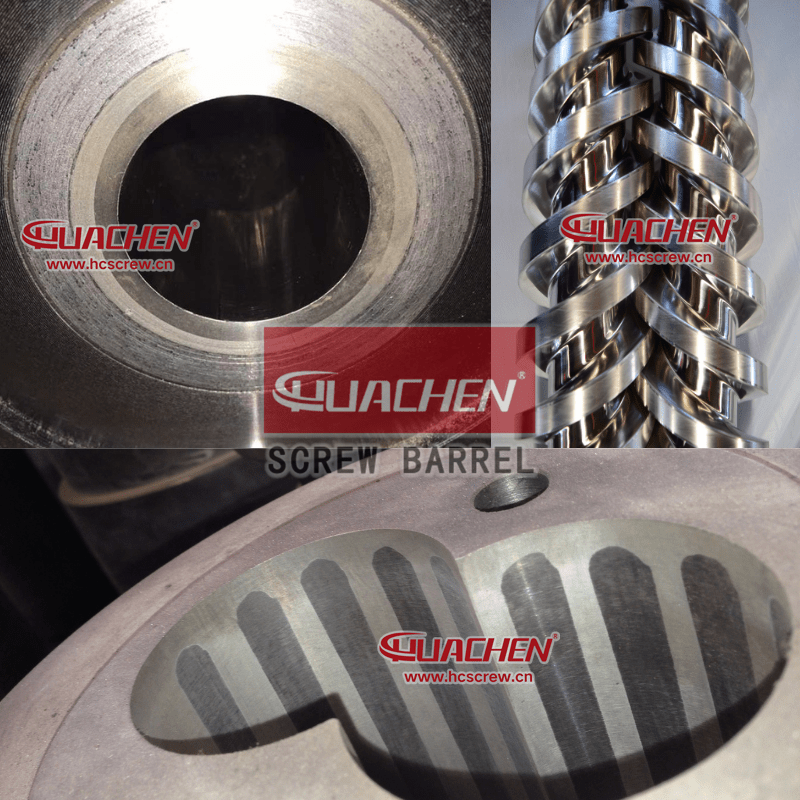

3. Bimetallic particles overlaid on screw barrel surfaces

It is possible to weld the screw overlay by electric arc welding, plasma welding, and other methods. Overlay alloys may be nickel alloy welding rods or cobalt alloy bars (such as Reiloyp48 alloy). Hardening the latter to HRC36-54 or overlaid directly on the former improves the hardness.

China screw barrel manufacturers have reported that overlay alloys can also be used to repair worn screws, which can be treated up to about 3 mm in diameter. When repairing screws, the cost is 35-70% of that of a new screw.

4. Spray coating with bimetallic particles

The screw treatment method is currently undergoing extensive research. It is possible to use nitrided steel screws, coated with a special bimetallic coating on the surfaces of the screw prongs or even on the entire screw matrix. Adding tungsten carbide to the coating material can further improve the screw’s wear resistance.

Pre-spray sandblasting with Al2O3 increases the adhesion of alloy material to the screw matrix. Using an oxygen-acetylene flame at 1750°C, the dispersed bimetallic particles are sprayed onto the screw surface in a completely melted or surface-melted state. Sintering is possible after spraying boron-containing materials because their melting point is only 1050–1070 °C. Due to this, the screw is capable of withstanding significant loads. It is not recommended to use chrome steel with a tendency to cold air harden when spraying followed by sintering. During cooling, the nominal spray alloy of this steel may crack.

5. Other screw treatment methods

There are a few screws that are carburised using the ancient surface carburizing process. As well, the newly developed boron carburising process is also beginning to be studied. However, due to the immaturity of the process, we will not introduce it here.

Summary

This article discusses nitride screws, bimetallic screws, and screw treatment methods. You can refer to the related reading to find out more about bimetallic screws. However, nitride screws have not been replaced by bimetallic screws and are still a reliable choice for some larger plastic products and extrusion screw barrels. If you are interested in finding out what the most suitable extrusion screw barrel is for your application, please contact us.

YOU MAY ALSO LIKE

| Bimetallic Alloy Screw Barrel ↗ Get details and latest price of bimetallic alloy screw barrel, heavy duty screw barrel, anti wear screw barrels and more at HUACHEN. |

| Hard Chrome Plating Screw Barrel ↗ Get details and latest price of hard chrome plating screw barrel, heavy duty chrome screw barrel, anti wear screw barrels and more at HUACHEN. |

| Ceramic Coating Alloy Screw Barrel ↗ Get details and latest price of ceramic coating alloy screw barrel, heavy duty ceramic tungstem screw barrels for SPC RVP, and more at HUACHEN. |

| SKD Screw Barrel ↗ Get details and latest price of SKD sleeve fitting screw barrel, high-filled PVC twin screw extrusion parts, anti-wear screw barrel at HUACHEN… |

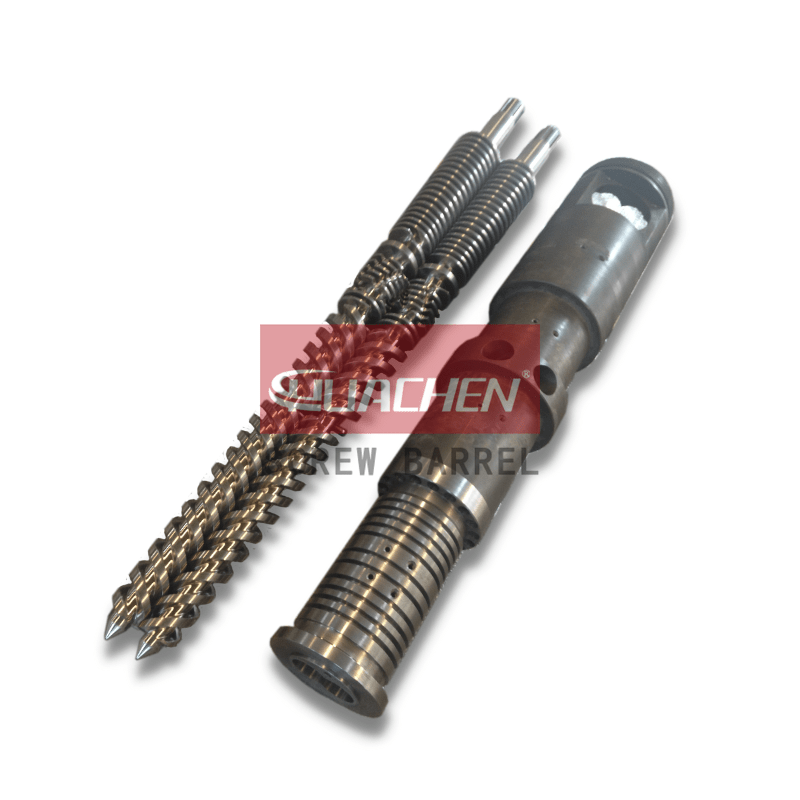

About the twin screw barrel Factory: HUACHEN

HUACHEN Screw has been a leading bimetallic alloy screw barrel manufacturer in Zhoushan Jintang since 1993. As one of the leading companies in designing and processing high strength extrusion spare parts screw barrel, HUACHEN Screw can provide its customers with a wide range of services, including drawing rebuilding, design, modification, and customized screw barrels. Our company has also successfully exported and supplied screw barrels to customers worldwide.

>>Learn more about our company

HUACHEN Screw Barrel Recent Post

- Boosting Efficiency and Quality: HUACHEN Screw Barrel’s Unmissable Showcase at HanoiPlas 2023

- Pipe Extrusion Operation: Best Practices for High-Quality Products

- Expert Maintenance Tips for Long-Lasting Bimetallic Alloy Screw Barrels

- Reviving Your Extruder: The Importance of Choosing the Right Screw Barrel Replacement

- Solutions to Common Production Problems for Rigid PVC Profiles and Pipes

- Customized Twin Screw Barrel with Internal Bore Grooves Sprayed with Bimetallic Alloy

- Troubleshooting Vent Flow Material Problems in PVC Profile Formation with Conical Twin Screw Extruders

- A Comprehensive Guide to Popular PVC Profiles and Their Production Methods

conical twin screw barrel extruder screw barrel extrusion screw barrel Foam sheet processing high speed screw barrel HUACHEN SCREW news injection screw barrel parallel twin screw barrel pa screw barrel pe making formula pe screw barrel plastic fiber processing plastic fibre screw barrel Plastic film making screw barrel plastic pipe processing Plastic profile processing Plastic raw material knowledge pp screw barrel PVC making formula pvc screw barrel related parts for screw barrel screw barrel engineering work screw barrel knowledge single screw barrel twin screw barrel

;