What is Bimetallic Screw Barrel?

Date:2022-8-11 Author:hcscrew

There are many screw barrel manufacturers who sell alloy screw barrels as well as bimetallic alloy screw barrel, and many customers request them for their extruders. However, most of them do not know what bimetallic treatment is or how to select it for their new screws and barrels.

In other words, what exactly is a bimetallic screw barrel?

To extend the life of screw barrels, bimetallic coatings are applied to the wear-prone areas, extending their service life. Bimetallic treatments are commonly used on screw barrels when producing plastic products such as PVC, PE, WPC, SPC, and equipment for extruding plastic recycled pellets.

There are a variety of bimetallic screw barrel types available. Bimetallic treatment can be applied to screws and barrels in several different ways. Do you know which ones you actually bought? What is the most suitable option for you? Each type of item has a different price (prices vary).

01. Overlay welding bimetallic alloy process for extrusion screws

HUACHEN Screw welding alloys are available in two types: one for welding the alloy to the screw prongs and one for welding the alloy to the screw surface. Weld alloys are available for electric solitary welding and plasma argon arc welding. The screw base material is 38CrMoAlA. After first tempering, it has a hardness of HV 250-270.

Furthermore, the term “bimetallic screw process” is just a generic term. There are many different formulations of bimetallic powders available. The most common alloys used today for screw overlays are Chinese standard welding wires 112 and 113, British standard cobalt-based carbide wire, and American standard RCoCr-A wire. Accordingly, we will design a range of bimetallic overlays and reinforcement locations on the screw based on the characteristics of different plastic materials and products.

Different bimetallic length

It is also possible to customise the length of the bimetallic on the screw. It is possible to apply bimetallic treatments to screws in one or more stages, or even to the entire screw. Bimetallic barrels are available in short and long lengths. Of course, the more bimetal used, the higher the price of the bimetallic screw barrel. In order to provide our customers with the most cost-effective bimetallic reinforcement solution, HUACHEN Screw Barrel continues to research and develop new products with bimetallic processes.

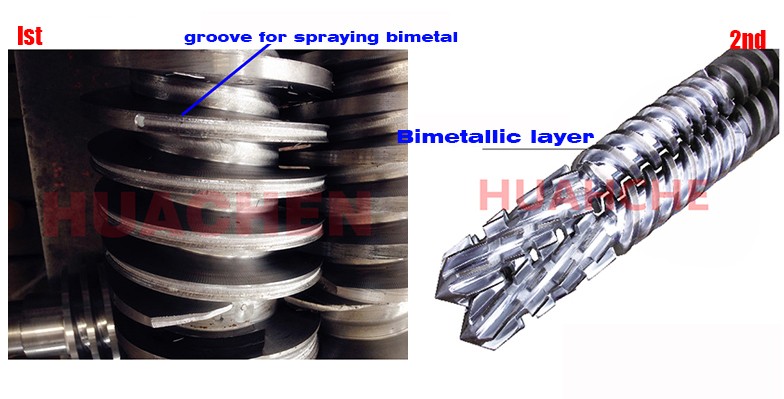

How bimetallic screws are processed

We need to cut grooves in the surface of the screw flights in order to closely overlay the bimetallic powder on the screw where the hardness needs to be reinforced. It is necessary to heat the screw to 550–600°C before welding. After that, the rotating flight surface of the screw is stacked with three layers of 1.5–2 mm thick cemented carbide stacked in three layers on top of a plastic and ductile Cr25Ni13 transition layer. The interlayer temperature is controlled between 550 and 600 °C. Immediately after welding, the screw goes into an electric furnace for annealing to relieve stress. It involves heating the weld layer to 650 °C for 1 hour, cooling it at 50 °C/hour, and then grinding it.

With many years of wear resistance practice, HUACHEN Screw has learned that screws with tungsten alloy, chromium alloy, and cobalt alloy layers can last 3 to 6 times longer than 38CrMoAlA nitrided screws.

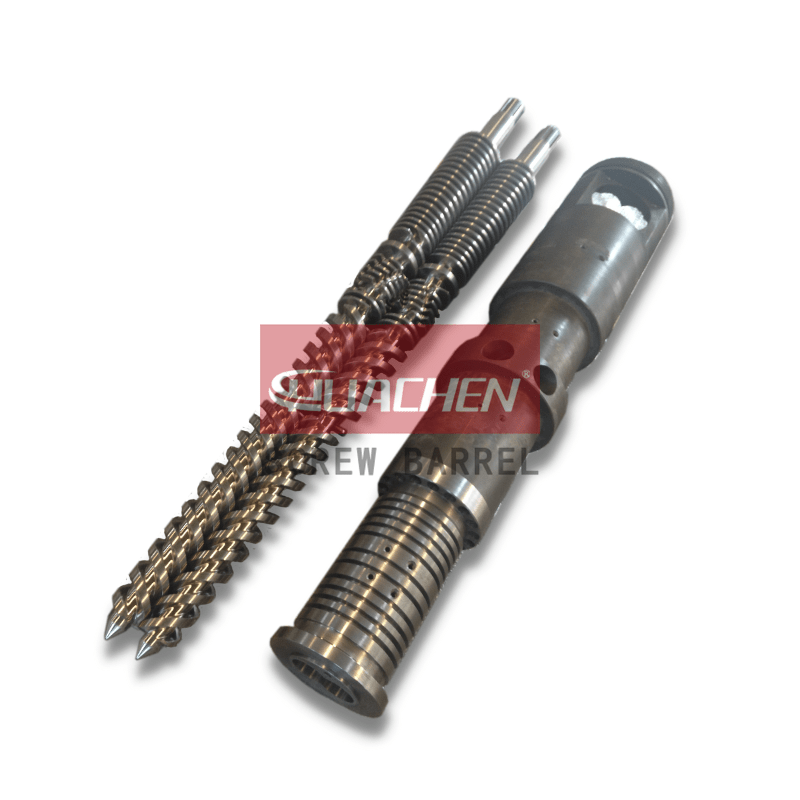

Bimetallic screw for PVC conical screw barrel

HUACHEN Screw Barrel’s PVC conical twin screw barrels are a good example. The conical twin screw barrel consists of four sections according to its function, namely the feeding section, the plasticizing section, the venting section, and the extruding section. It is a classic combination to have a grooved bimetallic layer barrel in the extruding section and one in the twin screw’s extruding section. A combination like this is ideal for the production of PVC profiles, PVC sheets, and PVC pipes with an intermediate filler (50–80%). In contrast, a barrel with a longer length of three-section bimetallic treatment is ideal for PVC profiles and PVC pipes with high filling additives.

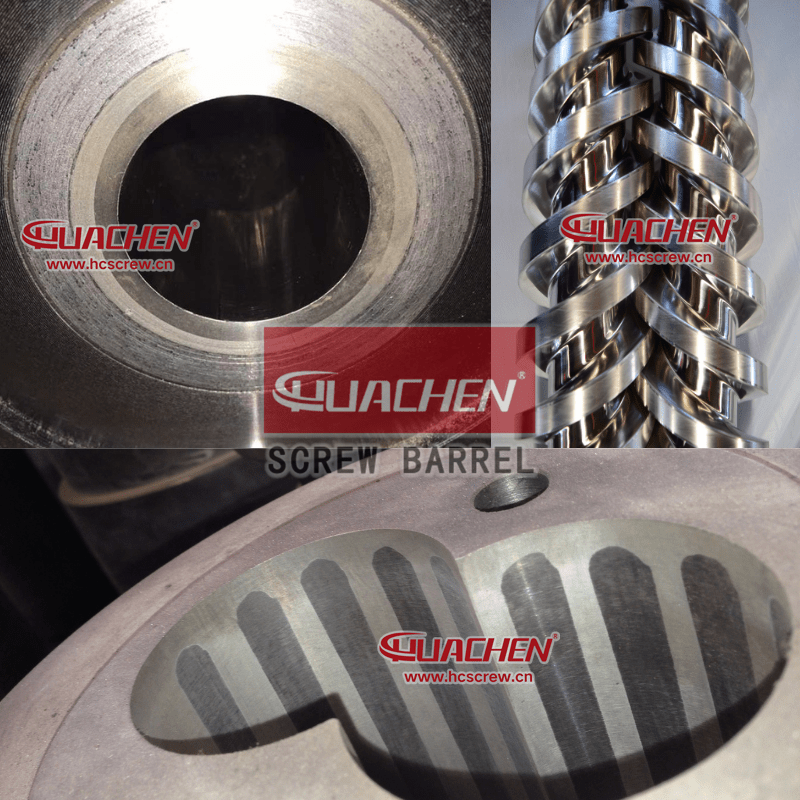

02. Alloy Centrifugal Casting process for single screw extrusion barrel

In order to increase the surface hardness of the bore of the single screw barrel, we use an alloy centrifugal casting process. The inner wall of the barrel is cast with an S38MnSIV layer using a centrifugal casting machine. This process creates a stronger connection between the alloy layer and the barrel as a whole, without heating or nitriding. Due to this, alloy centrifugal cast barrels are more expensive than grooved bimetallic layer barrels.

Based on HUACHEN Screw’s experience, this barrel is suitable for high-filled plastic materials as well as recycled plastic materials.

03. SKD Sleeve Fitted Barrel or Anti-Wear Materials Fitted Barrel

For optimal hardness, we will machine anti-wear sleeves in parallel twin screw barrels and conical twin screw barrels. You will need to tell our sales staff which type of barrel you require when you place your order.

The SKD tool steel material is a type of Japanese steel with a higher hardness than 38CrMoAlA. In order to achieve this, HUACHEN Screw inserts it into the barrel and inlays it into the barrel bore.

HUACHEN Screw has developed SKD tool steel sleeve fitted barrel technology for very high filled PVC and PE materials since 2012. It is necessary to treat SKD tool steel in a special way before inserting it into the barrel and polishing it.

There is an advantage to using the SKD sleeve or bush fitted barrel. There is a removable assembly segment on this barrel. Manufacturers of high-wear PVC products can return worn-out barrels to our factory for a new SKD sleeve fitted front barrel.

Furthermore, customers may select from a variety of SKD sleeve lengths and prices, as well as a one-stage SKD barrel, a two-stage SKD barrel, or a three-stage SKD barrel for their new SKD screw barrel.

YOU MAY ALSO LIKE

| Bimetallic Alloy Screw Barrel ↗ Get details and latest price of bimetallic alloy screw barrel, heavy duty screw barrel, anti wear screw barrels and more at HUACHEN. |

| Hard Chrome Plating Screw Barrel ↗ Get details and latest price of hard chrome plating screw barrel, heavy duty chrome screw barrel, anti wear screw barrels and more at HUACHEN. |

| Ceramic Coating Alloy Screw Barrel ↗ Get details and latest price of ceramic coating alloy screw barrel, heavy duty ceramic tungstem screw barrels for SPC RVP, and more at HUACHEN. |

| SKD Screw Barrel ↗ Get details and latest price of SKD sleeve fitting screw barrel, high-filled PVC twin screw extrusion parts, anti-wear screw barrel at HUACHEN… |

People also ask

HUACHEN Screw is sold directly from our factory in China for export. Please let us know the type of screw barrel you are using, the type of product you are producing, and the amount of filling, such as calcium powder. Our engineering staff will recommend the optimum anti-wear solution for your bimetallic screw barrel. Get the latest stock and pricing info from us.

Reception → screw barrel design checking and engineering service → prepare deposit → order manufacturing → quality control → finished product inspection → finished screw barrel checking → prepare balance payment → delivery → transportation

1. Business type: manufacturer, foreign trade company.

2. Origin: Zhoushan City, Zhejiang, China

3. Warranty: 12 months for fresh material.

4. International commercial terms: FOB, CFR, CIF, EXW

5. Scrcew barrel hs code: 8477900000

6. Terms of payment: T/T, L/C

7. Transport Package: AA Grade wooden case

You’ll get a reply from HUACHEN Screw within 1 hour or 24 hours.

About the twin screw barrel Factory: HUACHEN

HUACHEN Screw has been a leading bimetallic alloy screw barrel manufacturer in Zhoushan Jintang since 1993. As one of the leading companies in designing and processing high strength extrusion spare parts screw barrel, HUACHEN Screw can provide its customers with a wide range of services, including drawing rebuilding, design, modification, and customized screw barrels. Our company has also successfully exported and supplied screw barrels to customers worldwide.

>>Learn more about our company

More posts about what is bimetallic screw barrel: screw barrel engineering work, screw barrel knowledge

HUACHEN Screw Barrel Recent Post

- Boosting Efficiency and Quality: HUACHEN Screw Barrel’s Unmissable Showcase at HanoiPlas 2023

- Pipe Extrusion Operation: Best Practices for High-Quality Products

- Expert Maintenance Tips for Long-Lasting Bimetallic Alloy Screw Barrels

- Reviving Your Extruder: The Importance of Choosing the Right Screw Barrel Replacement

- Solutions to Common Production Problems for Rigid PVC Profiles and Pipes

- Customized Twin Screw Barrel with Internal Bore Grooves Sprayed with Bimetallic Alloy

- Troubleshooting Vent Flow Material Problems in PVC Profile Formation with Conical Twin Screw Extruders

- A Comprehensive Guide to Popular PVC Profiles and Their Production Methods

conical twin screw barrel extruder screw barrel extrusion screw barrel Foam sheet processing high speed screw barrel HUACHEN SCREW news injection screw barrel parallel twin screw barrel pa screw barrel pe making formula pe screw barrel plastic fiber processing plastic fibre screw barrel Plastic film making screw barrel plastic pipe processing Plastic profile processing Plastic raw material knowledge pp screw barrel PVC making formula pvc screw barrel related parts for screw barrel screw barrel engineering work screw barrel knowledge single screw barrel twin screw barrel

;