Removable SKD Sleeve Fitted Technology for Conical Twin Screw Barrel

Date:2022-9-23 Author:hcscrew

01 What is SKD sleeve fitted technology?

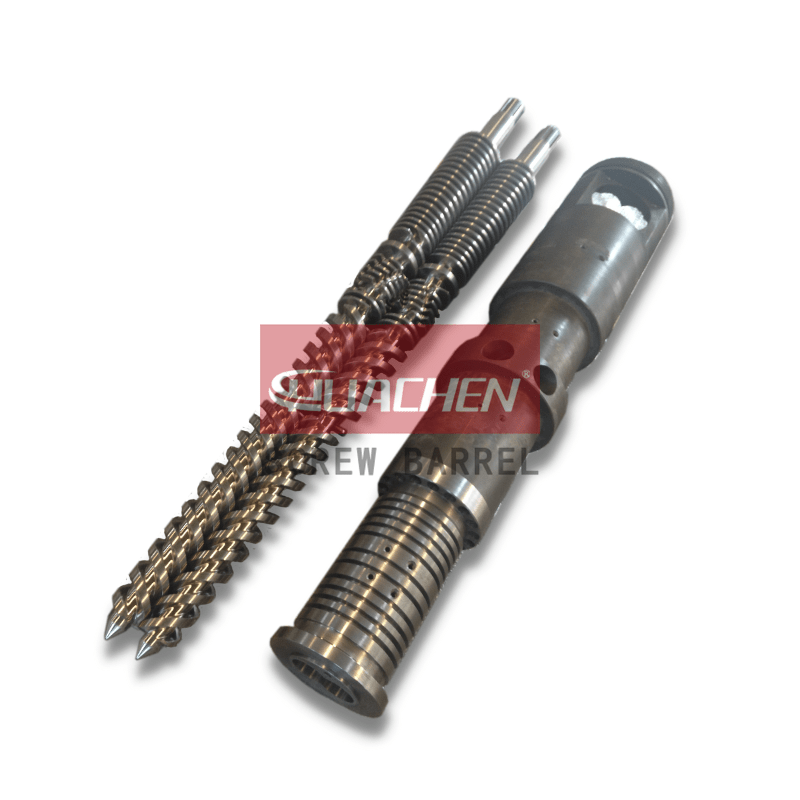

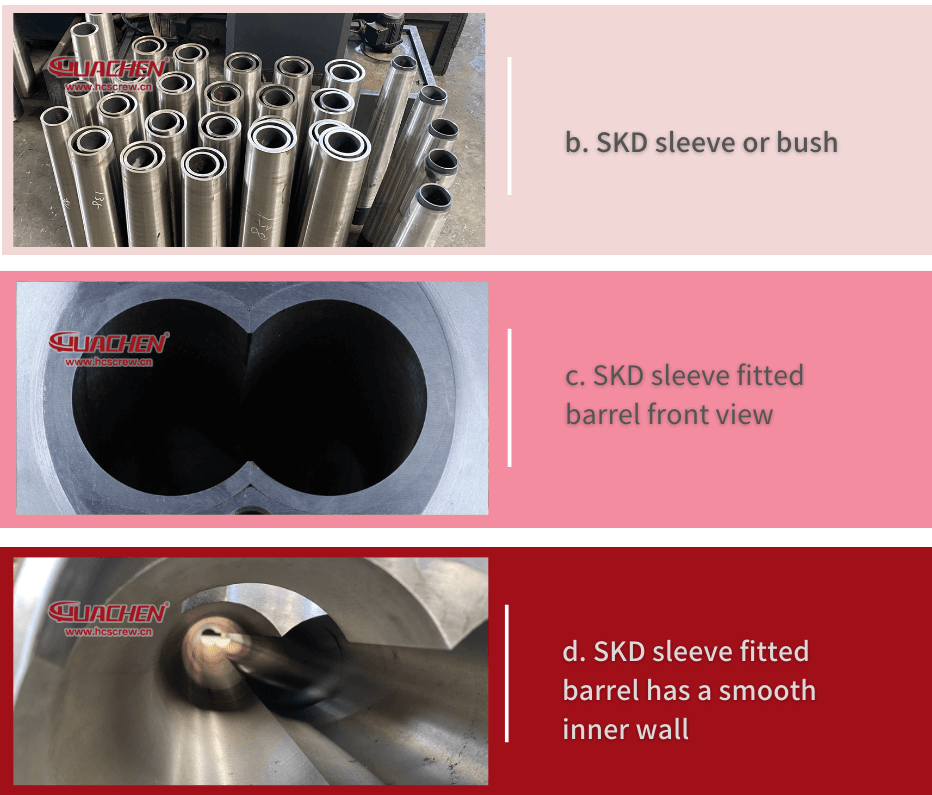

A technology developed by HUACHEN Screw in 2012 to inlay a conical twin screw barrel with a high wear-resistant base material. It is made into a conical and 8-shape sleeve, which is then inserted into the conical twin barrel bore to ensure that it fits closely. A SKD sleeve is particularly suitable for high-filling PVC products, due to its low wear rate.

Steels such as SKD11 and SKD61 are usually used for making this highly wear-resistant base material. China calls this type of barrel SKD sleeve fitted barrel, SKD barrel, or SKD screw barrel when it is paired with conical twin screw.

02 SKD sleeve fitted barrel features

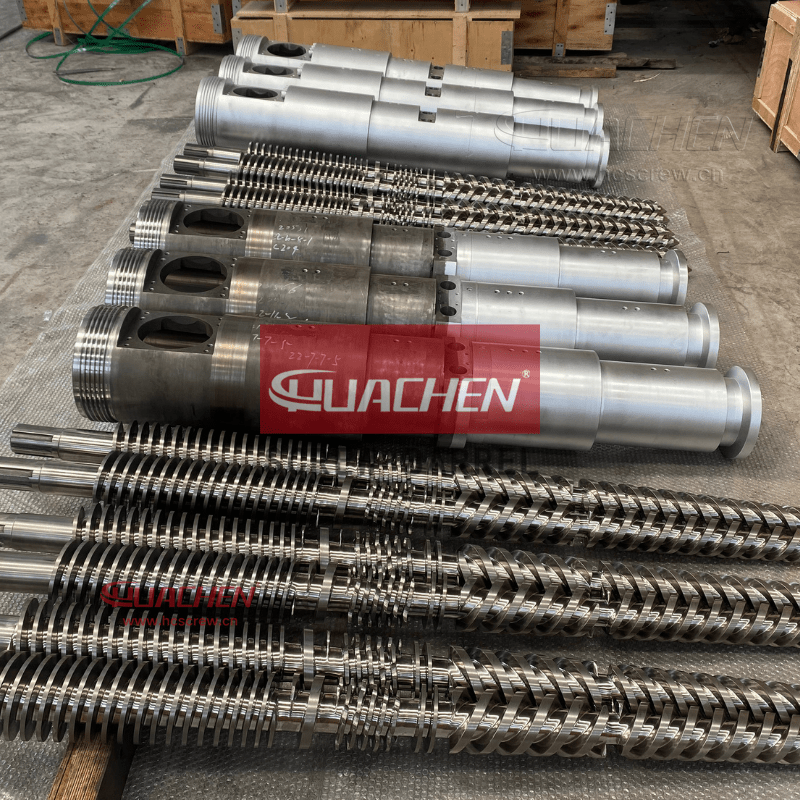

SKD sleeves or bushings are inserted into the bore of the barrel extrusion section. When producing high filling PVC products, the barrel’s extruding section is the most vulnerable to wear. A SKD barrel can come in a variety of lengths and can be classified as a one-stage SKD barrel, two-stage SKD barrel, or full-stage barrel depending on the range of applications where wear resistance is needed.

03 SKD sleeve fitted barrels have segmented barrel inlays as part of their design. What is the purpose of these removable barrel design?

1. To make the screw barrel price more reasonable. For cost and experience reasons, it is not ideal to use SKD tool steel as a screw barrel base material. For high filling PVC products, the conical twin screw barrels are too large, and SKD tool steel is too expensive. High filling PVC materials cause conical twin screw barrels to need replacement frequently. Due to its wear resistance, SKD tool steel is a reasonable choice for the barrel bore component. By using sleeve fitted barrel technology, we enable high filling PVC product extruder users to obtain more reasonable prices and reduce their purchase costs.

2. A more efficient way to process barrels. The barrel of a conical twin screw has a long length. Segmented barrel construction could make setting the SKD sleeve easier.

3. Designed to be removable and recyclable. SKD sleeve barrels can be replaced easily and quickly by removing the high-strength screws, which increases the barrel’s life and saves production costs.

04 What is the purpose of developing SKD sleeve fitted barrels?

Traditionally, PVC products are processed with bimetallic barrels and screws. The SKD sleeve fitted barrel was developed by HUACHEN Screw in 2012, making it more suitable for the extrusion of high filling polymers. On the basis of the bimetallic alloy screw barrel technology, SKD material was selected as the base material for the barrel bore anti-wear layer. The new SKD sleeve-fitted barrel lasts approximately 1.5-2 times longer than the original barrel at a cost increase of 20%, and it doesn’t fall off.

In 2012, China’s PVC market grew rapidly, resulting in the rapid development of the conical twin screw extruder market. PVC conical twin extruder users soon realized that high filling PVC materials wore out the barrels quickly. Barrels with conical twin screws have a short service life and screw barrel for high filling PVC materials need to be replaced every three to six months. As a result, PVC products cost more to produce. Furthermore, conical twin barrels can only process a limited range of PVC products due to the non-wearable screw barrel.

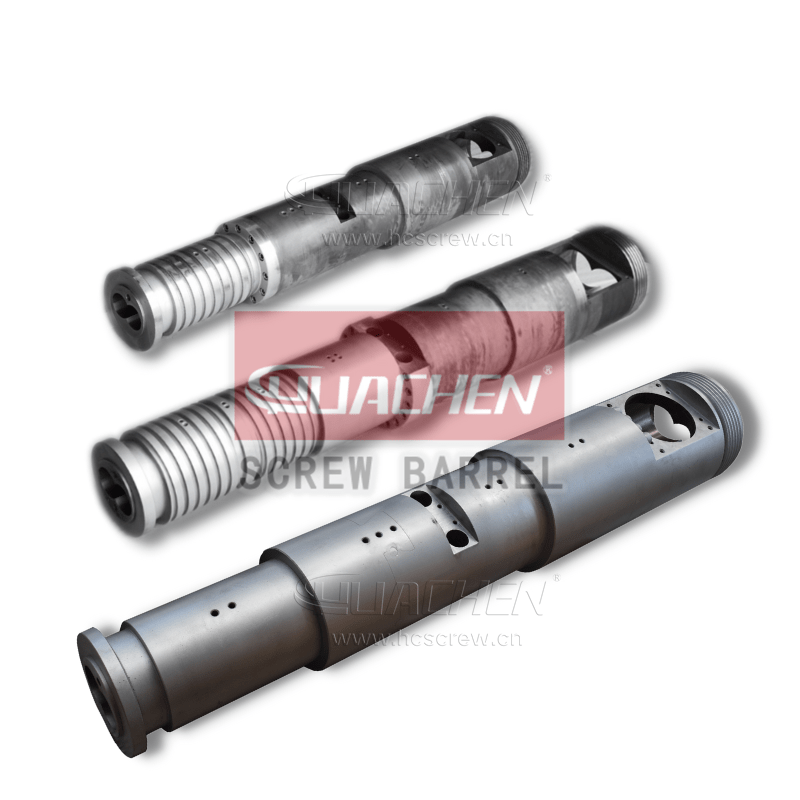

05 What is the purpose of inlaying SKD sleeves in the extruding section of the conical barrel bore?

A conical barrel’s inner bore is made up of two cylindrical cones, so the small head area – the extruding section – is subjected to greater pressure. To increase the service life of the extruding section of the barrel, we added SKD sleeves to the extruding section. This ensures that the four inner barrel sections wear at the same rate. That is, all four zones of the inner barrel wall must break down simultaneously. Additionally, even if the feed section of the conical barrel fails, the extruding section will remain functional. By doing this, the screw barrel lives exponentially longer.

Over the past few years, our SKD barrel users have learned how to replace the SKD sleeve fitted front barrel themselves, which has led to cost savings. In order to achieve this, HUACHEN Screw must produce barrels with high dimensional accuracy, flat and smooth inside walls. It is easy and quick to replace and assemble these barrels, so that high-fill PVC products can be extruded quickly and efficiently again.

06 What is SKD?

The two most common types of SKD material are SKD11 and SKD61. SKD11 is equivalent to American standard D2 tool steel or Chinese standard Cr12Mo1V1. SKD61 is equivalent to the American standard H13 tool steel, or the Chinese standard 4Cr5MoSiV1. SKD11 has a hardness of HRC62-64. On the barrel bore, it shows uniform wear. The hardness of SKD61 is HRC49-53, and it has high heat resistance, strength, and toughness. the field experience of our users, the overall performance of SKD11 tool steel is better than SKD61.

SKD11 tool steel grades from various countries:

| Countries and regions | Standards | Steel grades |

|---|---|---|

| China | GB | Cr12MoV |

| Chinese Taiwan | CNS | SKD11 |

| German | DIN | x165CrM0v12 |

| Japan | JIS | SKD11 |

| South Korea | KS | STD11 |

| Russia | ROCT | x12M |

| Italy | UN1 | x165CrM0W12KU |

| Sweden | SS | 2310 |

| Spain | UNE | X160CrM0V12 |

| USA | AISI/SAE | D2 |

The chemical composition of SKD11 tool steel:

| C | Si | Mn | Cr | Mo | V | P | S |

|---|---|---|---|---|---|---|---|

| 1.40-1.60 | 0.40max | 0.60max | 11.00-13.00 | 0.80-1.20 | 0.2-0.5 | 0.03max | 0.03max |

07 How are SKD screw made?

SKD61 is used to make “full hardened conical twin screws” with nitriding and hardening processes. However, we rarely select this option due to the long processing time required by the material properties. The reason for this is that SKD61 is an expensive raw material and is not suitable for manufacturing conical twin screws of larger sizes. The 38CrMoAlA nitriding steel screw is more suitable for use with high filling PVC products than the SKD61 screw.

08 How are SKD barrel made

SKD sleeve fitted barrel components are made separately. It includes the barrel jacket, the SKD sleeve or bush, the connection high strength screws, and the barrel back section. Next, the SKD sleeve is inserted into the conical twin screw barrel bore extruding section, so that it fits closely to the barrel’s inner wall. It results in a better surface hardness of the extruding section of the conical twin screw barrel. With the help of high strength screws, the sleeve-fitted front barrel is assembled to the barrel’s rear section. There should be no gaps in the bore of the barrel. Keeping the barrel clean will prevent material build-up, which can affect the plasticization of the PVC. It is also technically difficult to make the inlaid SKD sleeve surface smooth and flat.

09 What makes SKD sleeve fitted barrels difficult to manufacture?

1. SKD11 requires a higher level of hardening technology due to its physical characteristics.

2. SKD11 is hard but brittle, making polishing more difficult.

3. The SKD11 should be machined into two conical cylinders and assembled into a figure-of-eight sleeve without any gaps in the sleeve.

4. It is important that the inlay surface of the SKD11 sleeve be flat and smooth without any gaps in the bore of the barrel.

10 For single screw barrels and twin screw barrels of HUACHEN Screw, why is SKD sleeve fitting not recommended?

It is possible to use SKD tool steel for both single screw barrels and parallel twin screw barrels. To make groove feeding barrels, we produce grooved feed barrel sleeves from SKD tool steel. It is also possible to manufacture parallel twin screw barrels fitted with SKD sleeves to improve the barrel inner wall’s wear resistance. However, we do not recommend this.

The reason for this is that SKD11 and SKD61 are expensive materials. It takes more time and effort to polish components made of SKD tool steel because of its physical properties. Furthermore, the barrel length and diameter of single screws and parallel twin screws are quite large, which makes processing them difficult.

During the early years, HUACHEN Screw developed many SKD sleeve fitted barrels for single screw barrels and parallel twin screw barrels. The custom design received high customer responses, resulting in a good price acceptance rate. However, the long processing times make it more challenging to promote the SKD sleeve fitted barrel technology for parallel twin screw barrels and extrusion single screw barrels when compared to the traditional bimetallic alloy process. In other words, HUACHEN Screw’s bimetallic alloy barrels are good enough in terms of both price and performance.

11 Which plastic products require SKD sleeve fitted barrels?

1. Upgrade conical twin screw extruder with high speed and high efficiency design

2. Conical twin screw barrel for High filling PVC (200-350% addition), UPVC, RPVC pipes, profiles and sheets

3. Conical twin screw barrel for PVC wall panels, ceiling panels

4. Conical twin screw barrel for WPC profiles, window and door profiles and sheets

5. Conical twin screw barrel for SPC/RVP sheets

6. Conical twin screw barrel for PE corrugated pipes

7. Conical twin screw barrel for PVC and PE foam board, sheets

12 What are the results of using SKD sleeve fitted barrels?

When using screw barrel model 65/132 for rigid PVC pipes containing 250% or more calcium filler, the normal output of a bimetallic alloy conical twin screw barrel is 200-250 tons per month, whereas SKD sleeve fitting barrels coupled with bimetallic alloy conical screws yield 10,000 tons per month, with a maximum of 15,000 tons.

13 It is not just SKD that can make wear-resistant sleeves

There are many options available for SKD sleeves and bushings, including the commonly used SKD11 and SKD61.

In 2018, HUACHEN Screw developed a tungsten carbide alloy sleeve that applies the SKD sleeve fitting technology to barrel, and a ceramic alloy steel sleeve is already in use. Their benefits combine the advantages of SKD tool steel and the advantages of bimetallic alloys. The sleeves solve the technical challenges of processing SKD insert sleeves, and enhance the experience of processors of PVC products with high fillings. It is suitable for the extrusion of PVC foam boards, SPC, and WPC composite flooring due to its higher abrasion strength. The HUACHEN Screw Company is constantly developing and searching for new high performance wear resistant layer materials as well as updating sleeve fitted barrel technology. A technological revolution in PVC extrusion will result from this innovation.

Contact us for more information and quotes on the HUACHEN Screw SKD sleeve fitted barrel conical twin screw barrel!

YOU MAY ALSO LIKE

| RPVC, CPVC, UPVC Screw Barrel ↗ Get details and latest price of RPVC, CPVC, UPVC screw barrel, high speed design, better anti-wear and anti-corrosion screw barrel at HUACHEN… |

| SKD Screw Barrel ↗ Get details and latest price of SKD sleeve fitting screw barrel, high-filled PVC twin screw extrusion parts, anti-wear screw barrel at HUACHEN… |

| Difference Between SKD11 And SKD61 On Process Screw Barrel ↗ Get differences between tool steel SKD11 vs SKD61 on process screw barrel, SKD11 (D2) SKD61(H13) screw barrel characteristics and applications… |

People also ask

HUACHEN Screw is sold directly from our factory in China for export. Please let us know the type of extruder screw barrel you are using, the type of product you are producing and the amount of filling such as calcium powder. Our engineering staff will recommend the optimum anti-wear solution for your SKD screw barrel. We have a full stock of our top selling twin screw models and support 7 day delivery. Get the latest stock and pricing info from us.

Reception → screw barrel design checking and engineering service → prepare deposit → order manufacturing → quality control → finished product inspection → finished screw barrel checking → prepare balance payment → delivery → transportation

1. Business type: manufacturer, foreign trade company.

2. Origin: Zhoushan City, Zhejiang, China

3. Warranty: 12 months for fresh material.

4. International commercial terms: FOB, CFR, CIF, EXW

5. Scrcew barrel hs code: 8477900000

6. Terms of payment: T/T, L/C

7. Transport Package: AA Grade wooden case

You’ll get a reply from HUACHEN Screw within 1 hour or 24 hours.

TAGS

HUACHEN Screw Barrel Recent Post

- Boosting Efficiency and Quality: HUACHEN Screw Barrel’s Unmissable Showcase at HanoiPlas 2023

- Pipe Extrusion Operation: Best Practices for High-Quality Products

- Expert Maintenance Tips for Long-Lasting Bimetallic Alloy Screw Barrels

- Reviving Your Extruder: The Importance of Choosing the Right Screw Barrel Replacement

- Solutions to Common Production Problems for Rigid PVC Profiles and Pipes

- Customized Twin Screw Barrel with Internal Bore Grooves Sprayed with Bimetallic Alloy

- Troubleshooting Vent Flow Material Problems in PVC Profile Formation with Conical Twin Screw Extruders

- A Comprehensive Guide to Popular PVC Profiles and Their Production Methods

conical twin screw barrel extruder screw barrel extrusion screw barrel Foam sheet processing high speed screw barrel HUACHEN SCREW news injection screw barrel parallel twin screw barrel pa screw barrel pe making formula pe screw barrel plastic fiber processing plastic fibre screw barrel Plastic film making screw barrel plastic pipe processing Plastic profile processing Plastic raw material knowledge pp screw barrel PVC making formula pvc screw barrel related parts for screw barrel screw barrel engineering work screw barrel knowledge single screw barrel twin screw barrel

;