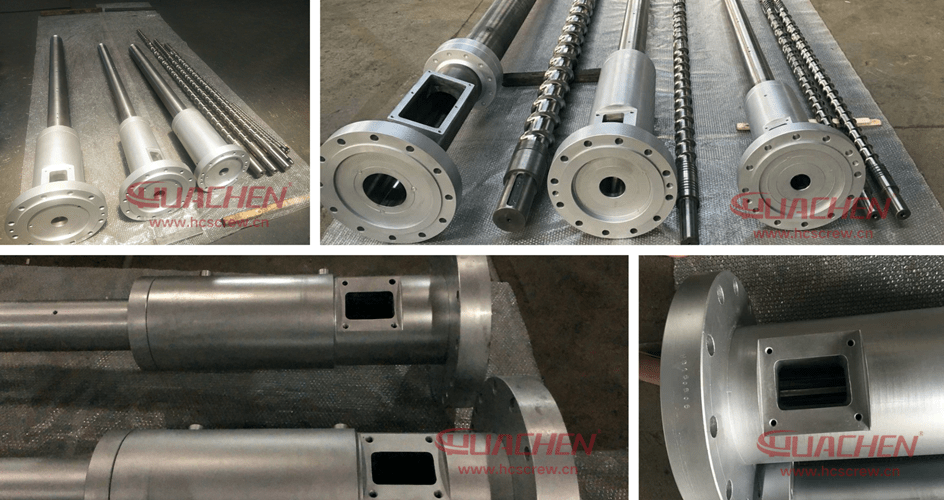

Grooved Feeding Barrel

● Sale and assembly with grooved feed extrusion barrel

● Pipes extrusion

● Sheets extrusion

● Recycling pelletizing extrusion

● PE / HDPE / PP

You Need Better Grooved Feed Barrel at Good Price!

- Product Detail

HUACHEN Screw has been a leading Grooved Feeding Barrel manufacturer in Zhoushan Jintang since 2005. With many years of experience in the design and processing of plastic machinery accessories, HUACHEN Screw can provide its customers with a wide range of services including screw barrel design, rebuilding, modification, and upgrade. Our company has also successfully exported and supplied screw barrels to customers worldwide.

>>Learn More About Our Company

Grooved Feeding Barrel

We commonly refer to this type of barrel as a High Efficiency High Speed Extruder Barrel in China. In other words, this barrel design uses a faster screw speed to achieve a higher output. The barrel structure has a unique design that provides superior conveying efficiency, excellent plastification performance, high melt homogeneity, low energy consumption, and a 20 – 40% higher output per minute than a standard barrel.

A grooved feeding barrel has a flange, a forced circulation cooling system, a feed port, and a melting section. There are grooves on the inside of the barrel. Variable depth grooves can be as long as the barrel or as long as the forced circulation cooling system. Depending on the characteristics of the plastic material and the required productivity, grooves can be rectangular, trapezoidal, triangular, circular, linear, or spiral.

The barrel’s forced circulation cooling system is located in the feeding section. With the cooling medium introduced, the friction between plastic material and barrel and screw quickly removes the excess heat. The material is conveyed at a low temperature as a result. It is designed according to the characteristics of the plastic material and its coolant effect directly affects the barrel conveying efficiency.

Due to the high feed section pressure, the grooved barrel extruder screw and barrel must be precisely designed to balance wear rates. It also requires a high level of sealing due to the forced circulation cooling system. Screw barrel manufacturers, therefore, have high process requirements.

Our barrels are equipped with wear-resistant layers on the inner wall grooves. Wear-resistant layers are produced in a variety of ways, including sprayed alloy treatment, grooved feeding bush or sleeve inserts, or welding. This reduces barrel wear and extends its service life. Further, we offer a new type of barrier screw that is capable of withstanding high torques and strong forces.

Application of Grooved Feeding Barrel

The grooved feeding barrel is best suited for HDPE, PP, and ABS pipe materials. HUACHEN Screw’s continuous development enables it to produce both granular and powdered materials, as well as irregularly shredded plastic.

We can upgrade your conventional extruder to a high-speed grooved barrel screw, but a larger gearbox is required to start the same diameter screw barrel. For a customised solution, please contact our engineers.

Applicable materials: PVC (PVC-U, SPVC), PE, PP, ABS, PC, PA, PET, PTFE, etc.

1. With general-purpose screws: drain pipes, gas pipes, threaded pipes, transparent hoses, medical hoses, PP-R pipes, POM pipes, etc.

2. With barrier screws: single and double wall corrugated pipe, solid wall pipe, steel belt pipe, etc.

3. With vented screws: transparent PMMA tubes, PC tubes, PC lampshades, ABS tubes, etc.

4. With screws for special engineering plastics: PTFE tubes, PVDF tubes, etc.

Grooved Feeding Barrel Specifications

1. Single screw L/D ratio available: 30 to 40

2. Barrel max. length: ≤10000 mm

3. Barrel max. out diameter: ≤350 mm

4. Based materials: Premium 38CrMoAlA (UNS K24065, SACM645, 41CrAlMo7-10),SKD

5. Plasma nitriding surface hardness: HV 1000-1100

6. Plasma nitriding depth: ≥ 0.7 mm

7. Nitriding fragility: less than Grade I.

8. Surface Roughness: Ra 0.4 μm

9. Screw Linearity: ≤ 0.015mm

10. Alloy depth: 2-4 mm

11. Alloy surface hardness: ≥ HRC 61

>>Learn more about our grooved feeding barrel parameters

Our groove feeding barrel ultimate solution for abrasion and wear:

1. Alloy steel of high strength, tempered and nitride.

2. bimetallic barrel: grooved feed sleeve process

3. bimetallic barrel: centrifugal casting alloy base process.

4. HSS sleeve barrel: SKD insert feeding sleeve process.

>>Learn more about our bimetallic screw barrel treatments

Production time:

Complete set of grooves feeding barrel within 30-38 days depending on the complexity of the part.

You can get creative with our selection of products at good prices. We guarantee the quality of our grooved feeding barrels for sale. Our grooved feeding barrels are made in China by the China Origin Factory. If you have any questions, please feel free to contact us.