Difference Between SKD11 And SKD61 On Process Screw Barrel

Date:2022-9-19 Author:hcscrew

There are many different types of steel used to manufacture screws and barrels, and each has its own application. Selecting the right steel grade is a technical task in the extrusion industry. Chinese screw barrel users commonly abbreviate their tool steel screw barrels as SKD to indicate their high wear resistance. Customers often misunderstand SKD by believing that the higher the grade number, the better. So, let HUACHEN Screw Barrel Factory, a professional SKD screw barrel manufacturer, explain the differences between SKD11 and SKD61 tool steel. It is our hope that you, the users of high filler screw barrels, will find this information useful when selecting your screw barrel material.

01 SKD11 (D2) VS SKD61 (H13)

A simple definition would be, SKD11, equivalent to American standard D2, or Chinese standard Cr12Mo1V1. SKD61 is the equivalent of the American standard H13, or the Chinese standard 4Cr5MoSiV1. Clearly, the two uses are different! Cold work tool steel SKD11 has an HRC of 62-64 hardness. It is durable and wear-resistant. SKD61 is a hot work tool steel with a hardness of HRC 49-53 and high heat resistance, strength, and toughness.

02 SKD11 (D2) Application

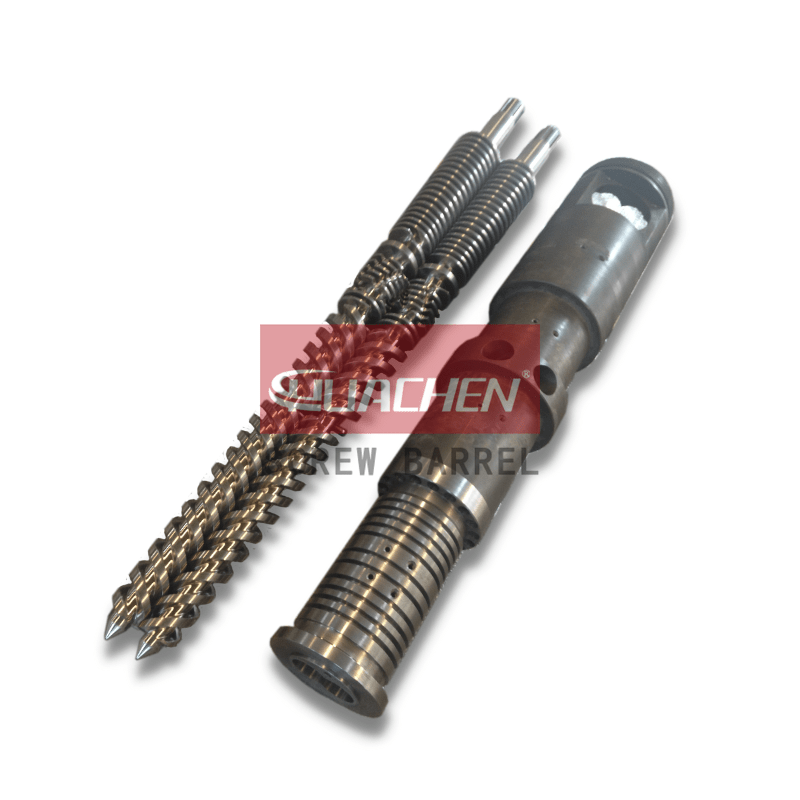

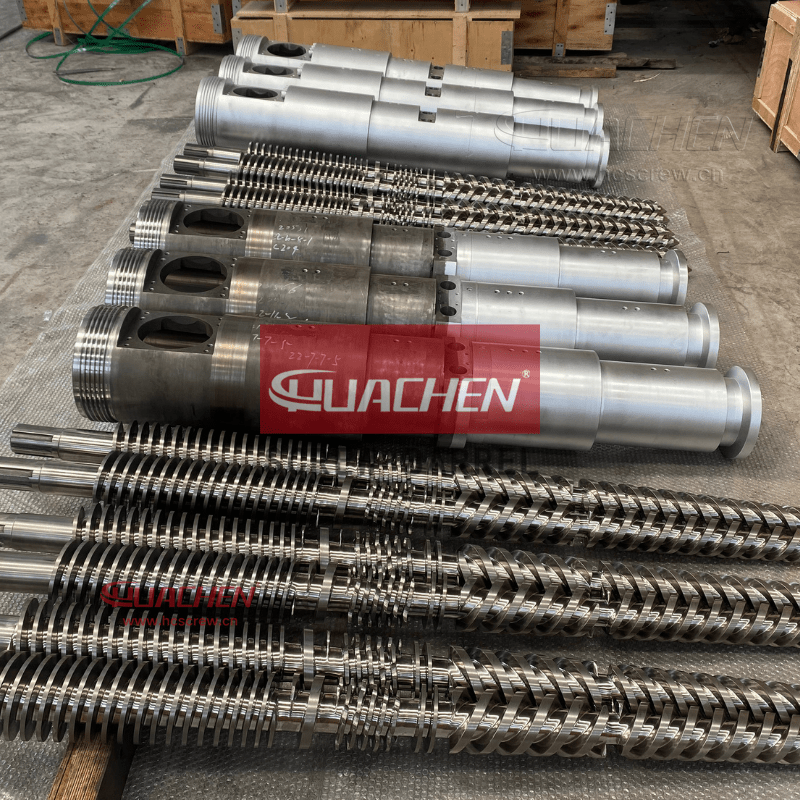

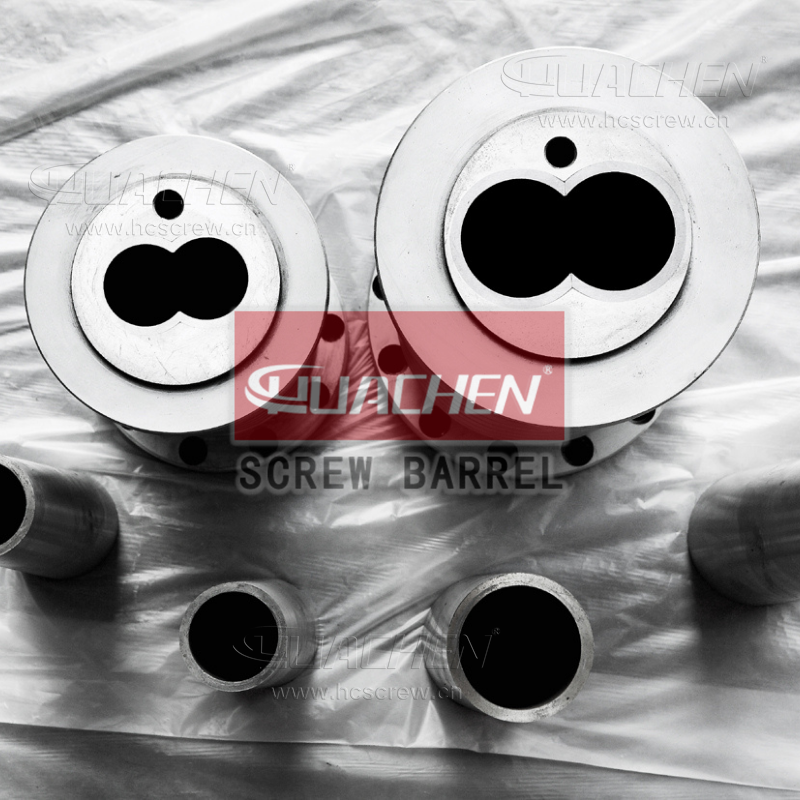

In extruder screw barrels, SKD11 is used as a base material for conical twin screw barrels, parallel twin screw barrels, and groove feeding barrels. SKD11 material is made into a conical or cylindrical shape of “∞” sleeve, which is then inserted into a conical twin screw barrel. It makes the barrel less prone to wear and tear during use and more suitable for rigid PVC materials and high speed extruder. The barrel is known as the SKD Sleeve Fitted Barrel. It consists of the same high-performance screws as the SKD Screw Barrel.

The screws made from SKD61 screws are known as Fully Hard Screws and are generally used in injection moulding machines to process engineering plastics. The engineering plastic raw material contains a large percentage of glass fibre and requires a high-grade wear and corrosion resistant solution.

SKD11 is a high-carbon, high-chromium alloy tool steel with good wear resistance, dimensional stability, and hardenability. At high temperatures, it’s tough and resistant to fatigue. Suitable for long-term use at high temperatures, it can withstand temperature fusion. Well-suited for cutting and polishing. It can be blanked into sleeves or bushes for inlay. Additionally, it can produce embossed dies, scissors, inlay inserts, woodworking inserts, thread rollers, and wear-resistant slides for cold heading, thermosetting resin forming, advanced gauges, and other deep drawing forms and cold extrusions.

03 SKD61 (H13) Application

With its fine, moderate grain structure and largely distributed carbide grains, SKD61 has exceptional mechanical properties. It contains silicon, chromium, molybdenum, and vanadium. Due to their high hardening performance, the moulds are capable of producing large sizes and complex shapes.

The characteristics of SKD61 include high temperature strength and toughness, improved wear resistance, and ease of cutting. In recent years, isotropic products have become increasingly popular, as have high-toughness materials. By using SKD61, screws can last longer, perform more consistently, and are easier to process, since there is a small amount of heat treatment deformation.

It is pertinent to consider several factors when selecting SKD steel. In addition, users should understand the basic characteristics of SKD screws and barrels. Before choosing an SKD screw barrel, consider the application areas and requirements of SKD steel. It is also important to choose a professional quality manufacturer along with a screw barrel supplier so that the SKD screw barrel can better demonstrate its qualities and effects.

Summary

Here is an overview of SKD11 (D2) and SKD61 (H13) tool steel screw barrel materials, one of the tool steel used to manufacture screws and barrels. Please contact us if you would like more information or a quote on high wear resistance and high performance SKD screw barrels.

YOU MAY ALSO LIKE

| RPVC, CPVC, UPVC Screw Barrel ↗ Get details and latest price of RPVC, CPVC, UPVC screw barrel, high speed design, better anti-wear and anti-corrosion screw barrel at HUACHEN… |

| SKD Screw Barrel ↗ Get details and latest price of SKD sleeve fitting screw barrel, high-filled PVC twin screw extrusion parts, anti-wear screw barrel at HUACHEN… |

| Removable SKD Sleeve Fitted Technology for Conical Twin Screw Barrel ↗ Get know removable SKD sleeve fitted technology on conical twin screw barrel, tool steel screw barrel, SKD11, SKD61 screw barrel advantages… |

People also ask

HUACHEN Screw is sold directly from our factory in China for export. Please let us know the type of extruder screw barrel you are using, the type of product you are producing and the amount of filling such as calcium powder. Our engineering staff will recommend the optimum anti-wear solution for your SKD screw barrel. We have a full stock of our top selling twin screw models and support 7 day delivery. Get the latest stock and pricing info from us.

Reception → screw barrel design checking and engineering service → prepare deposit → order manufacturing → quality control → finished product inspection → finished screw barrel checking → prepare balance payment → delivery → transportation

1. Business type: manufacturer, foreign trade company.

2. Origin: Zhoushan City, Zhejiang, China

3. Warranty: 12 months for fresh material.

4. International commercial terms: FOB, CFR, CIF, EXW

5. Scrcew barrel hs code: 8477900000

6. Terms of payment: T/T, L/C

7. Transport Package: AA Grade wooden case

You’ll get a reply from HUACHEN Screw within 1 hour or 24 hours.

More posts about SKD11 and SKD61 on process screw barrel:

HUACHEN Screw Barrel Recent Post

- Boosting Efficiency and Quality: HUACHEN Screw Barrel’s Unmissable Showcase at HanoiPlas 2023

- Pipe Extrusion Operation: Best Practices for High-Quality Products

- Expert Maintenance Tips for Long-Lasting Bimetallic Alloy Screw Barrels

- Reviving Your Extruder: The Importance of Choosing the Right Screw Barrel Replacement

- Solutions to Common Production Problems for Rigid PVC Profiles and Pipes

- Customized Twin Screw Barrel with Internal Bore Grooves Sprayed with Bimetallic Alloy

- Troubleshooting Vent Flow Material Problems in PVC Profile Formation with Conical Twin Screw Extruders

- A Comprehensive Guide to Popular PVC Profiles and Their Production Methods

conical twin screw barrel extruder screw barrel extrusion screw barrel Foam sheet processing high speed screw barrel HUACHEN SCREW news injection screw barrel parallel twin screw barrel pa screw barrel pe making formula pe screw barrel plastic fiber processing plastic fibre screw barrel Plastic film making screw barrel plastic pipe processing Plastic profile processing Plastic raw material knowledge pp screw barrel PVC making formula pvc screw barrel related parts for screw barrel screw barrel engineering work screw barrel knowledge single screw barrel twin screw barrel

;