How To Install Conical Twin Screw Barrel On Extruder?

Date:2022-3-31 Author:hcscrew

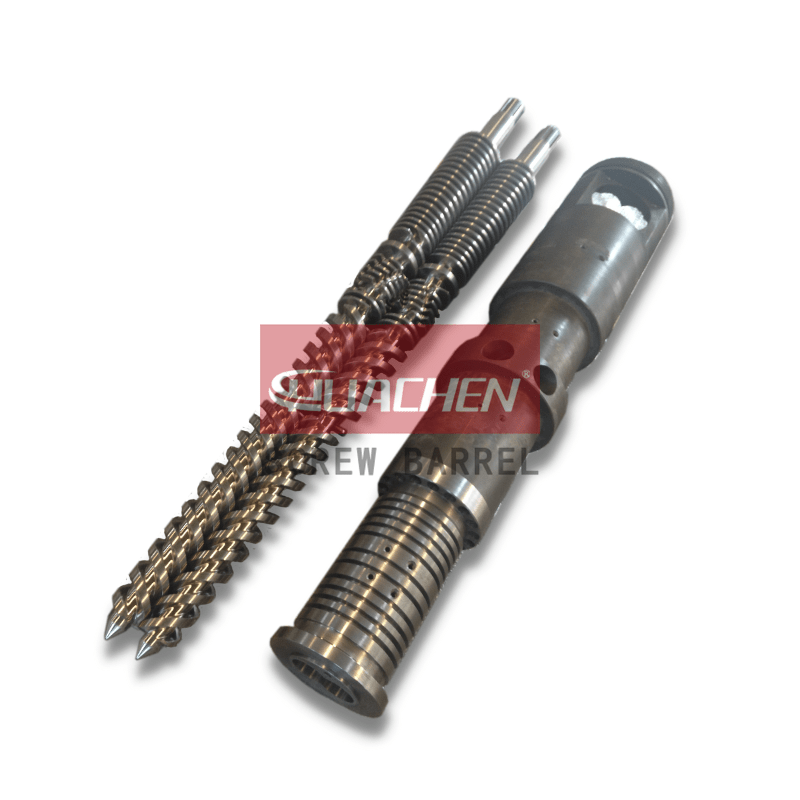

Users of conical twin screw barrels should understand how to install them in an extrusion. Conical twin screw extrusion offers the obvious benefit of manufacturing high-filler PVC products.

Then, how do we install the conical screw barrel on the extruder?

Today, HUACHEN Screw Barrel Factory demonstrates how to install a conical screw barrel and explains the most important key to conical screw and barrel installation.

Let’s get the new conical twin screw barrel installed on the extruder.

01. Install the Conical Twin Screw’s Barrel

1. Make sure the barrel is horizontal.

First and foremost, ensure that the conical twin screw extruder frame remains horizontal. Check to see if it is securely fastened.

Key point 1: make sure the conical twin screw barrel is horizontal!

It is important to ensure that the conical screw’s barrel is horizontal. It indicates the pressure between the twin screw and the barrel is distributed equally. If the conical screw’s barrel is inclined non-horizontally, the conical screw that is under more pressure will break sooner than the other. That’s why some customers complain, “Oh, one of my screws cracked after 3 months, there’s a quality problem.”

Key point 2: How do you make the barrel horizontal?

In the image above, look at the clearance of 6, which is the gap between the extruder gearbox and the barrel’s end. Make sure that all of the mounting distances add up to 1=2, 3=4, 5=6, which indicates that your conical twin screw barrel is horizontal. If it doesn’t stay the same, make the necessary adjustments to the extruder bracket.

2. Install the barrel support frame

Install the front and back support frames of the barrel in the correct positions. Place the barrel on the platform of the host extruder. Install the front and rear moving devices by tightening the tiny fixing screws.

3. Standard barrel height

Measure the centre height of the front and back ends of the conical twin screw barrel using the height ruler. Please use the gearbox’s distribution box’s centre height as the norm.

4. Gearbox to barrel connection

Push the barrel to the connecting portion with the distribution box after deciding the foregoing things. Please double-check that the connection is correct.

02. Install The Conical Twin Screws

1. Determine if the barrel of the conical twin screw is installed correctly.

The conical twin screws must now be installed. Open the conical twin-screw barrel’s big nut and pull out the barrel. Put two conical twin screws, one on each side, separated into right and left conical screws. Place the left and right conical screws in the barrel’s left and right holes, respectively. It’s worth noting that the conical twin screw rotates in the opposite direction, outward.

2. Locate the conical twin screw shank’s reference point.

On the spline of the screw shank, there is a defined plane. The reference point is the centre of the spline. The two screws’ reference points should be vertically aligned and looking upward.

3. Locate the output shaft shank of the distribution box’s reference point.

The reference point is located in the middle of a designated flat key on the output shaft spline. The reference points of the two shafts should be aligned with the reference points of the two screws and should face upwards vertically side by side.

4. The screw’s reference point is vertically upward.

Place twin screws at the bottom of the barrel where the required distance exists. The small head of the conical twin screw should be at the front of the barrel at this point.

| Model | 45/100 | 51/105 | 55/110 | 65/132 | 80/156 | 92/188 |

|---|---|---|---|---|---|---|

| N1 (mm) | 3-5 | 4-6 | 4-6 | 4-6 | 7-9 | 8-10 |

5. Push the small head screw tip into the conical twin screw barrel’s small end.

This is the N1 distance. Please adjust the standard screw barrel spacing according to the axial movement distance chart for different conical twin screw barrel types. Hold the left screw in place while adjusting the right screw back and forth. You may use the percentage table to calculate the right screw’s moving distance L.

6. Install the two gaskets at the end of two screws with the fixing screws.

Install the two gaskets at the end of two screws with the fastening screws. Tighten the barrel’s big nut. At the same time, tighten the two screws into the extruder gearbox distribution box. Replace the left screw. Rotate the right screw toward the barrel’s small head. Measure the right screw’s F1 moving distance, then replace the right screw and tighten it. Measure the distance between the left screw and the left screw F2. L must equal the sum of F1 and F2, i.e. L=F1+F2.

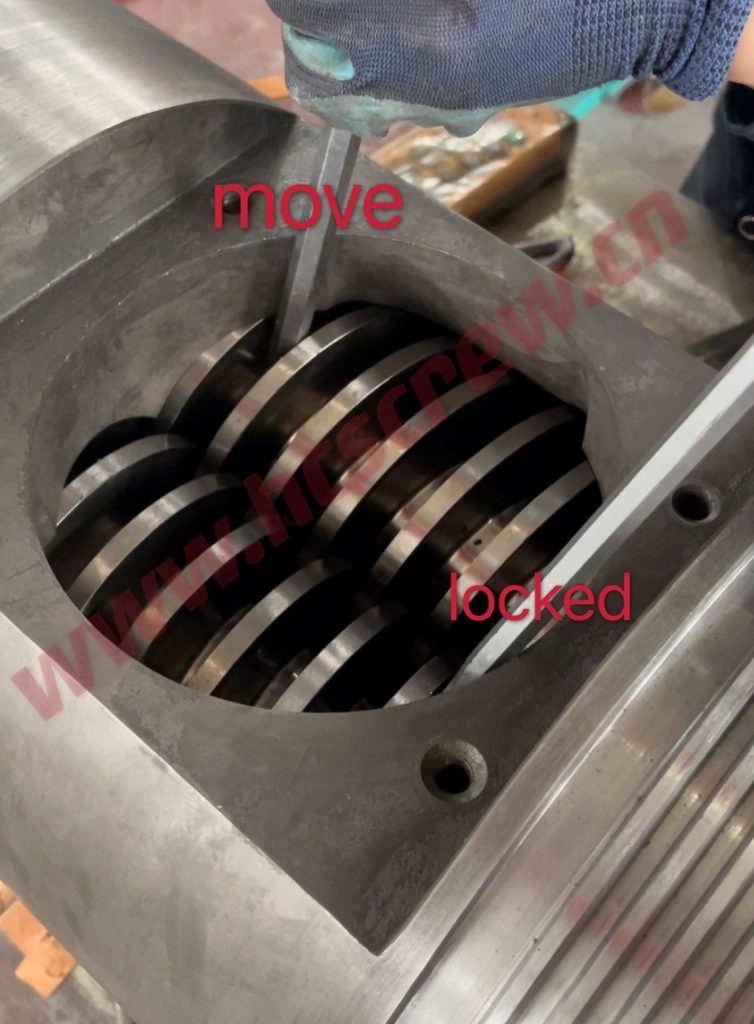

Key point: What’s the best way to put a conical twin screw in a match state?

Push the left conical screw in all way to the back of the gearbox. To reach gap 1, use two tools: one to lock the left conical screw and the other to move the right conical screw. Put the right conical screw to the gearbox side’s end. To feel the difference between gap 2 and gap 1, lock the right conical screw with two tools and rotate the left conical screw.

To reach the gearbox at the same distance, both conical screws must be adjusted, i.e. 1=2.

If 1>2, you’ll require more force to change and move the right conical screw, as well as the gaskets at the left screw’s conical screw shank’s end.

7. Install and adjust the screw shank gaskets.

The thickness of the two gaskets at the conical twin screws’ ends can be adjusted. Depending on the distance required, you can increase or reduce the number of gaskets, finally making F1=F2=1/2L. That is, the distance between two forward-moving screws is the same.

8. Install the striker plate on the barrel.

Install the barrel striker plate, conical twin screw, and barrel striker plate fixed set (or external circulation oil sleeve) to correct the installation, then advance the screw. The output shaft of the distribution box is lined up with the screw’s reference point. Then tighten the barrel big nut with the spline sleeve. Make sure the installation is accurate.

Thank you for your time. To acquire a video illustrating how to install a conical screw barrel on an extrusion, request a price or contact HUACHEN Screw Barrel.

YOU MAY ALSO LIKE

| Conical Twin Screw Barrel ↗ Get latest & most competitive prices on China conical twin screw barrel, extruder barrels, extruder screw, bimetallic screw, SKD barrels. |

People also ask

HUACHEN Screw is sold directly from our factory in China for export. Please let us know the type of extruder screw barrel you are using, the type of product you are producing, and the amount of filling such as calcium powder. Our engineering staff will recommend the optimum anti-wear solution for your SKD screw barrel. We have a full stock of our top selling conical twin screw barrel models and support 7-day delivery. Get the latest stock and pricing info from us.

Reception → screw barrel design checking and engineering service → prepare deposit → order manufacturing → quality control → finished product inspection → finished screw barrel checking → prepare balance payment → delivery → transportation

1. Business type: manufacturer, foreign trade company.

2. Origin: Zhoushan City, Zhejiang, China

3. Warranty: 12 months for fresh material.

4. International commercial terms: FOB, CFR, CIF, EXW

5. Scrcew barrel hs code: 8477900000

6. Terms of payment: T/T, L/C

7. Transport Package: AA Grade wooden case

You’ll get a reply from HUACHEN Screw within 1 hour or 24 hours.

About the twin screw barrel manufacturer: HUACHEN

HUACHEN Screw Manufacturing Co., Ltd. is located in the beautiful coastal city of Thousand Islands, Jintang Town, Zhejiang Province, China. It is also China’s largest plastic and rubber screw and barrel production base.

With more than 23 years of experience in plastic chemical engineering, our factory focuses on producing HUACHEN brand bimetallic barrels, SKD sleeve fitted barrel, bimetallic alloy screw barrel, and various single screw barrel series. Plastic extruders, injection moulding machines, and other machines employ the products.

HUACHEN Screw Barrel Recent Post

- Boosting Efficiency and Quality: HUACHEN Screw Barrel’s Unmissable Showcase at HanoiPlas 2023

- Pipe Extrusion Operation: Best Practices for High-Quality Products

- Expert Maintenance Tips for Long-Lasting Bimetallic Alloy Screw Barrels

- Reviving Your Extruder: The Importance of Choosing the Right Screw Barrel Replacement

- Solutions to Common Production Problems for Rigid PVC Profiles and Pipes

- Customized Twin Screw Barrel with Internal Bore Grooves Sprayed with Bimetallic Alloy

- Troubleshooting Vent Flow Material Problems in PVC Profile Formation with Conical Twin Screw Extruders

- A Comprehensive Guide to Popular PVC Profiles and Their Production Methods

conical twin screw barrel extruder screw barrel extrusion screw barrel Foam sheet processing high speed screw barrel HUACHEN SCREW news injection screw barrel parallel twin screw barrel pa screw barrel pe making formula pe screw barrel plastic fiber processing plastic fibre screw barrel Plastic film making screw barrel plastic pipe processing Plastic profile processing Plastic raw material knowledge pp screw barrel PVC making formula pvc screw barrel related parts for screw barrel screw barrel engineering work screw barrel knowledge single screw barrel twin screw barrel

;