WPC Wood Plastic Composite Extruder Conical Twin Screw Barrel

● PVC / PE / WPC, virgin or recycled materials, foam extrusion process

● Filler ratio of 200-300%, and greater than 300%.

● Min. Order (MOQ): 2 conical screws + 1 barrel

● Based material: Premium 38CrMoAlA tempered and nitrided, SKD11

● Anti-wear solution: SKD sleeve fitted barrel + bimetallic screw, bimetallic barrel + bimetallic screw, chrome coating screw, ceramic alloy screw

You Need Better Conical Twin Screw Barrel at Good Price!

- Product Detail

HUACHEN Screw offers a conical twin screw barrel for wood plastic composite extruders. It lets you make 1. all WPC products made of PVC or PE with wood flour; 2. You can manufacture WPC profiles and WPC wall panels by changing the product formula and screw barrel design; 3. It’s also possible to make WPC foam boards and WPC flooring. We offer a conical twin screw barrel that can be adapted to the WPC extruders of many well-known plastic machine manufacturers and ancillary manufacturers based on the WPC material’s features. Improve your performance.

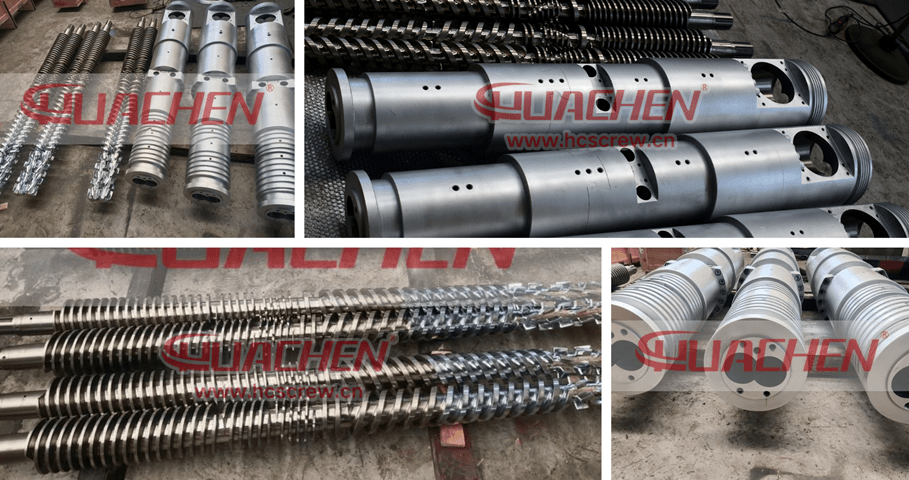

WPC wood plastic composite extruder conical twin screw barrel

1. Our conical twin screw has a special compression ratio and screw thread design for WPC wood plastic products. Supports the extrusion of wood plastic profiles, foam boards, and flooring using WPC pellets as raw material.

2. WPC screw barrels are designed for low shear and high conveying. It’s possible to make thick or solid WPC sheets. It has excellent plasticizing capacity, so you can make as much as you want.

3. There’s a vent port on the barrel so WPC raw materials can be extruded without getting wet. This keeps WPC products looking good and improves their surface gloss and hardness.

4. Optimize the screw and barrel’s anti-wear ability. The base material is high quality 38CrMoAlA, which is strictly tempered and nitrided. WPC special screw barrels have higher wear and corrosion resistance and longer service lives.

5. We offer standard and the latest high efficiency conical twin screw barrel models in 65, 80, 92 and more. All of them use standard assembly dimensions and are easy to install. We’ve fine-tuned WPC screw barrel designs based on region and country. Get in touch if you want to know more.

Application

WPC sheet or board conical twin screw extruder; WPC profile conical twin screw extruder; WPC wall panel and siding conical twin screw extruder; WPC foam sheet or board conical twin screw extruder; WPC composite decking, flooring conical twin screw extruder.

Manufacture of WPC wood plastic composite extruder conical twin screw barrel

| Model | Screw speed (rpm) | Motor (kW) | Capacity (kg/h) | Screw length (mm) | Barrel length (mm) | Weight (kg) | Package dimension (m) |

|---|---|---|---|---|---|---|---|

| HCZS65/132 | 34.7 | 37 | 380 | 1701 | 1480 | 410 | 1.8*0.3*0.4 |

| HCZS80/156 | 34.7 | 55 | 500 | 2116 | 1850 | 775 | 2.2*0.4*0.5 |

| HCZS92/188 | 34.7 | 110 | 800 | 2805 | 2520 | 1500 | 3.0*0.5*0.6 |

Our WPC wood plastic composite screw barrel ultimate solution for abrasion and wear

1. Alloy steel of high strength, tempered and nitride.

2. Bimetallic alloy screw barrel. Overlay of tungsten carbide alloy on wearable screw parts with a thickness of 4 to 6 mm. Effectively provide 1.5 times longer service life. bimetallic layer processing on barrel input opening section available.

3. hard chrome plating screw process.

4. Ceramic coating alloy screw process.

Materials

1. Based materials: Premium 38CrMoAlA, SKD11, SKD61

2. Plasma nitriding surface hardness: HV 1000-1100

3. Plasma nitriding depth: ≥ 0.7 mm

4. Nitriding fragility: less than Grade I.

5. Surface Roughness: Ra 0.4 μm

6. Screw Linearity: ≤ 0.015mm

7. Alloy depth: 4-6 mm

8. Alloy surface hardness: ≥ HRC 61

>>Learn more about our WPC wood plastic composite extruder conical twin screw barrel parameters

Production time

Ready stock model within 7 days, and custom-made model within 30 days depending on the complexity of the part.

HUACHEN Screw has been a leading conical twin screw barrel manufacturer in Zhoushan Jintang since 1993. As one of the leading companies in designing and processing conical twin screw extruder spare parts screw barrel, HUACHEN Screw can provide its customers with a wide range of services, including drawing rebuilding, design, modification, and customized screw barrels. Our company has also successfully exported and supplied screw barrels to customers worldwide. We are the China origin factory of WPC wood plastic composite extruder conical twin screw barrel. If you have any questions, please feel free to contact us.