SKD Screw Barrel

● Min. Order (MOQ): 2 screws + 1 barrel / set

● PVC, RPVC, UPVC, WPC, SPC

● Pipe, profile, sheet extrusion

● Compound pelletizing, recycling pelletizing

● HDPE Corrugated pipe extrusion

You Need Better SKD Screw Barrel at Good Price!

- Product Detail

HUACHEN Screw has been a leading SKD screw barrel manufacturer in Zhoushan Jintang since 2005. We have developed SKD sleeve or bush fitting barrel technology for rigid PVC product manufacturers since 2013. HUACHEN Screw offers a wide variety of services to its customers. We design, rebuild, modify, and upgrade screw barrels. Additionally, we have successfully exported screw barrels around the world.

>>Learn More About Our Company

SKD Screw Barrel

Our SKD screw barrel set is ideal for users of conical twin extruders for high filled PVC and PE, particularly for producers of PVC with a filling capacity of more than 200%. PVC products with high fill levels require our SKD screw barrels.

The SKD screw barrel refers to the SKD sleeve barrel with sleeve fitted barrel technology made of tool steel and a matching high-strength bimetallic alloy screw.

The screw and barrel are more durable and tougher in the areas where they are most likely to wear. This process extends the service life of the barrel and screw by uniformly slow wear.

In the production of high filled PVC, SKD represents the tool steel SKD11 and SKD61, which have wear-resistant properties.

>>Learn more about SKD sleeve fitting barrel technology

Based on the PVC formulation and filling ratio, we offer three different lengths of SKD sleeve fitting barrels.

Matching bimetallic alloy screws for SKD barrels

Bimetallic alloy screws are used in conjunction with SKD barrels to overlay the wear-prone areas with a composite formulation of bimetallic alloy. Our bimetallic alloy screws must also maintain the same wear rate as the SKD barrel because of its excellent wear resistance.

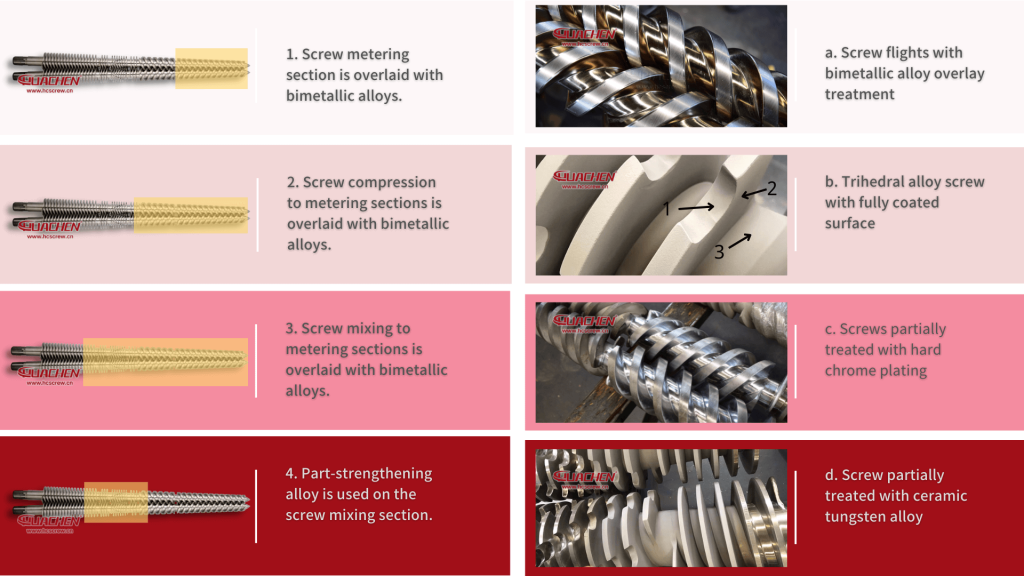

The user has a choice of five types of bimetallic alloy screws, depending on the type and amount of PVC used.

1. One-section bimetallic alloy treated screw

2. two-sections bimetallic alloy treated screw

3. three-sections bimetallic alloy treated screw

4. Partially reinforced alloy treatment

5. three-sided alloy treatment

>>Learn more about our bimetallic alloy screw

Application of SKD screw barrel

1. Upgrade conical twin screw extruder with high speed and high efficiency design

2. Conical twin screw barrel for High filling PVC pipes (200-350% addition), UPVC or RPVC pipes, PVC profiles and sheets

3. Conical twin screw barrel for PVC wall panels, ceiling panels

4. Conical twin screw barrel for WPC profiles, window and door profiles and sheets

5. Conical twin screw barrel for SPC/RVP sheets

6. Conical twin screw barrel for PE corrugated pipes

7. Conical twin screw barrel for PVC and PE foam board, sheets

The standard models of conical twin screw barrels for the above applications are in stock. To confirm the best price and delivery time, please contact us.

Specification

1. Based materials: Premium 38CrMoAlA, temperate and nitride.

2. Barrel sleeve materials: SKD11, SKD61, Tungsten carbide alloy steel

3. Plasma nitriding surface hardness: HV1000-1100

4. Plasma nitriding depth: ≥ 0.7mm

5. barrel sleeve surface hardness: ≥ HRC 62

6. barrel sleeve thickness: 6-10 mm

7. Alloy depth: 4-6 mm

8. Alloy surface hardness: ≥ HRC 61

>>Learn more about our screw barrel parameters

We have a wide selection at good prices to help you get creative. The SKD screw barrel is guaranteed to be of high quality. We are the China Origin Factory of SKD screw barrels. If you have any questions, please feel free to contact us.