Wear Resistant Barrel Sleeve, SKD Sleeve or Bush

● PVC, RPVC, UPVC, WPC, SPC

● Pipe, profile, sheet extrusion

● Compound pelletizing, recycling pelletizing

● HDPE Corrugated pipe extrusion

You Need Better Wear Resistant SKD Sleeve Fitting Barrel at Good Price!

- Product Detail

HUACHEN Screw has been a leading wear resistant barrel sleeve manufacturer in Zhoushan Jintang since 2005. For high filler PVC product manufacturers, we have developed SKD sleeve or bush fitting barrel technology since 2013. HUACHEN Screw offers a wide variety of services to its customers. We design, rebuild, modify, and upgrade screw barrels. Additionally, we have successfully exported screw barrels around the world.

>>Learn More About Our Company

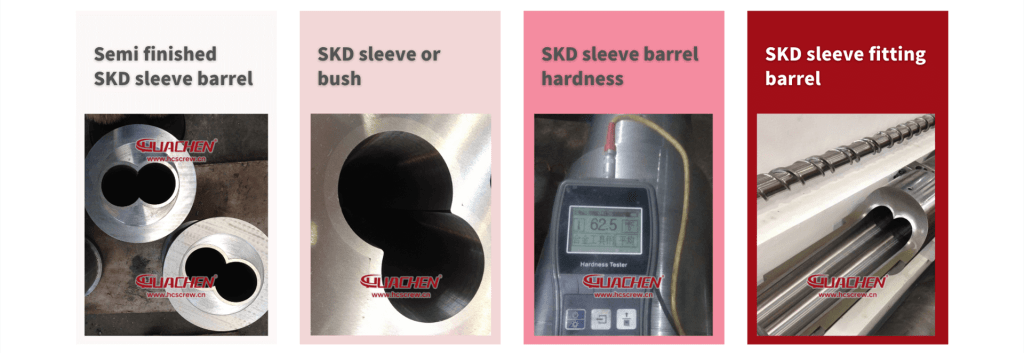

Wear Resistant Barrel Sleeve

Today, the traditional bimetallic conical twin screw barrel and parallel twin screw barrel anti-wear solutions are not suitable for the use of high filling PVC. Materials with fillings of over 200 parts are severely abrasive to the barrel’s extruding section. As a result, the plasticization of the material and output from the extruder are reduced, affecting the quality of the product. The extruding section of the barrel wears out, requiring replacement of the barrel, which increases production costs.

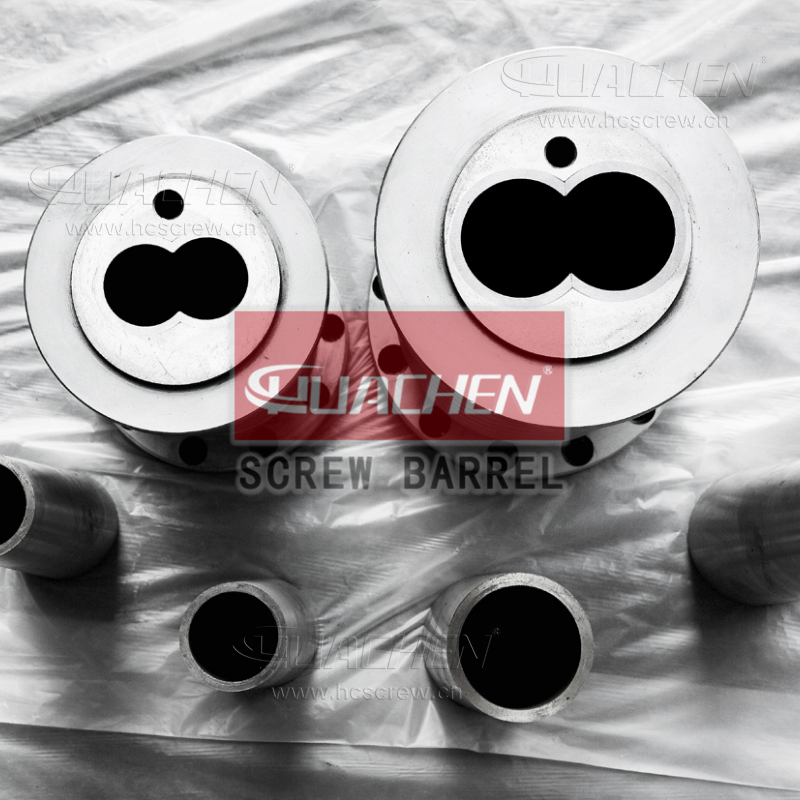

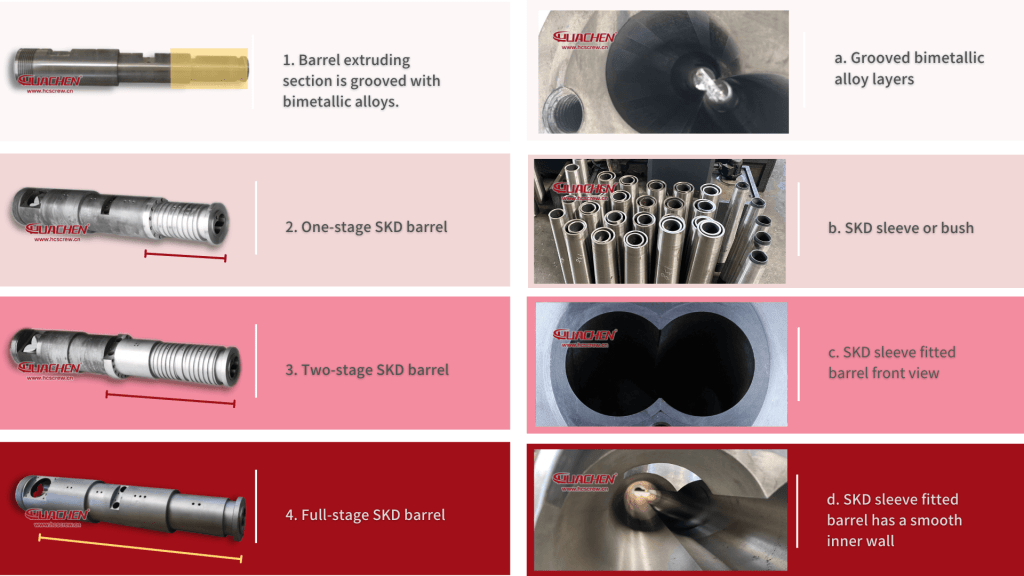

As part of the process, we use a high wear-resistant base material made into conical or cylindrical figure-of-eight sleeves that are inserted into the inner bore of the conical barrel. Due to this, conical barrels are less prone to wear during use and can be used to extrude highly filled materials.

With the same material and PVC processing formula, the barrel with the high wear resistant barrel sleeve-SKD sleeve or bush increases the service life by about 1.5 to 2 times compared to a traditional bimetallic barrel at a 20% increase in cost. The wear-resistant sleeves are also very stable and do not fall off easily.

>> Learn more about our SKD sleeve fitted barrel technology

SKD sleeve or bush

Wear-resistant base materials include SKD11 (upgraded D2) and SKD61, as well as upgraded wear-resistant composite alloy metal bushings, and new materials are constantly being developed. The selection of these depends on the material’s strength requirements.

An SKD sleeve has a surface hardness of HRC 62 and is available in thicknesses from 6 to 10 mm. For highly filled PVC products, we recommend SKD11, which has the highest combination of hardness, toughness, and surface finish. The price is also more reasonable.

SKD sleeves or bush are also used when machining grooved feed barrels, which are then set into the water jacket to improve wear resistance.

We specialize in wear resistant barrel sleeves, SKD sleeves or bush

1. twin screw extrusion barrel

3. Pipes, profiles, sheets, recycling pellet extrusion

4. HDPE corrugated pipe manufacturing

5. Wood plastic composite, WPC door, window, flooring sheet manufacturing

6. Stone plastic composite, SPC sheet, flooring board manufacturing

7. High efficiency high speed grooved feed extrusion barrel

8. HDPE extrusion

Specification

1. barrel sleeve materials: SKD11, SKD61, S38MnSIV

2. Plasma nitriding surface hardness: HV1000-1100

3. Plasma nitriding depth: ≥ 0.7mm

4. barrel sleeve surface hardness: ≥ HRC 62

5. barrel sleeve thickness: 6-10 mm

>>Learn more about our SKD sleeve or bush fitting barrel parameters

Production time:

Complete SKD sleeve or bush fitting barrel within 20 days depending on the complexity of the part.

We have a wide selection at good prices to help you get creative. The wear resistant barrel sleeve-SKD sleeve or bush is guaranteed to be of high quality. We are the China Origin Factory of wear resistant screw barrel. If you have any questions, please feel free to contact us.